Metalworking operations rely heavily on cutting tools to shape and manipulate workpieces effectively. Utilizing premium cutting tools can significantly enhance the precision and efficiency of these processes. With May 2022 U.S. cutting tool consumption totaling $175.4 million, it’s evident that industries are investing in quality tools for optimal performance. Join us as we explore the benefits of premium cutting tools, the types available, and how to choose the right one for your specific needs.

Benefits of Premium Cutting Tools

When using premium cutting tools, one can experience a significant enhancement in precision, efficiency, and cost-effectiveness. Let’s delve into the advantages these tools offer:

Enhanced Precision

- Improved Accuracy: Premium cutting tools ensure precise cuts and shapes, leading to impeccable end results.

- Consistent Performance: These tools maintain their accuracy over time, providing reliable performance for various machining operations.

Increased Efficiency

- Faster Operations: By utilizing premium cutting tools, operators can expedite the metalworking processes without compromising on quality.

- Reduced Downtime: The reliability of these tools minimizes unexpected downtimes, ensuring continuous workflow and productivity.

Cost-Effectiveness

- Long-Term Savings: Investing in premium cutting tools initially may seem costly, but their durability and efficiency lead to long-term cost savings.

- Reduced Waste: With precise cuts and efficient operations, there is a significant reduction in material waste, optimizing resources effectively.

These benefits are not just theoretical; real-life results from different customers across various industries have shown improved efficiency and accuracy when using cutting tools. Market trends also indicate an increased focus on efficiency and accuracy in cutting tools to meet industry demands. Expert advice emphasizes that maintaining cutting tools properly leads to efficient machining processes and a high return on investment.

Types of Cutting Tools

Linear Cutting Tools

Linear cutting tools play a crucial role in metalworking operations, offering precision and versatility. Let’s explore two common types of linear cutting tools:

Tool Bits

Tool bits are essential components in machining processes, known for their durability and efficiency. They are versatile cutting tools that can be used for various applications, including shaping, drilling, and milling. With premium tool bits, operators can achieve precise cuts and shapes with ease, enhancing the overall quality of the workpiece.

Broaches

Broaches are specialized cutting tools designed to produce complex shapes and profiles with high accuracy. They are commonly used in keyway cutting and gear shaping applications. By utilizing premium broaches, manufacturers can ensure consistent performance and exceptional surface finishes on their workpieces.

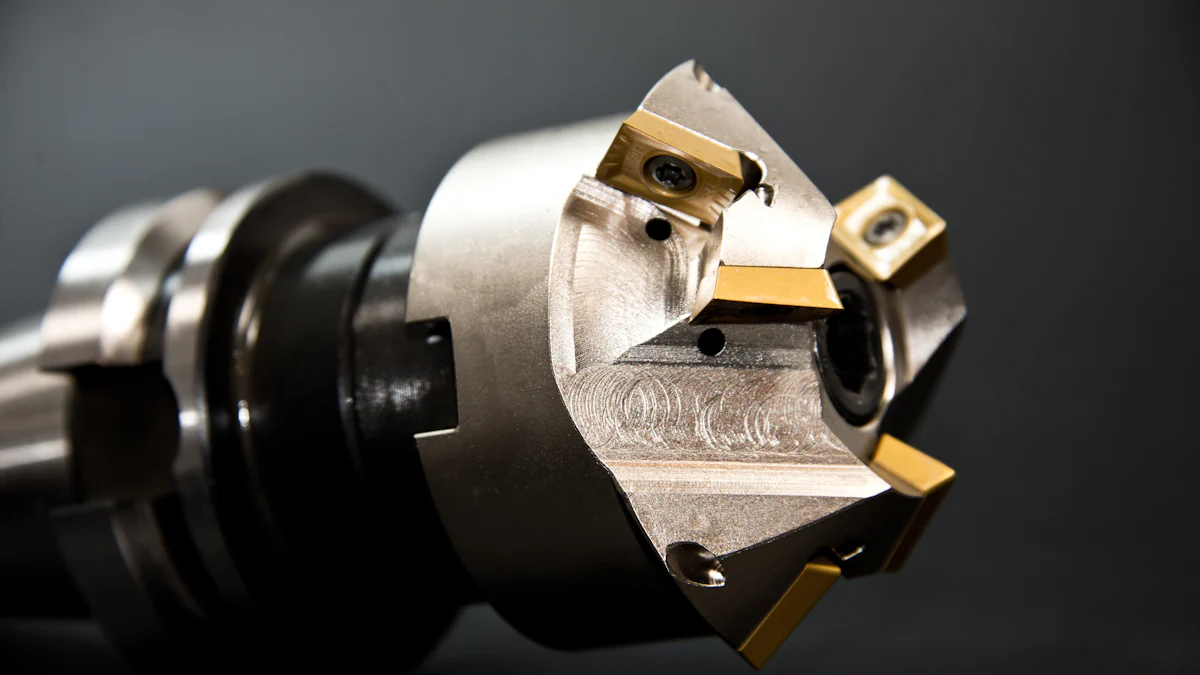

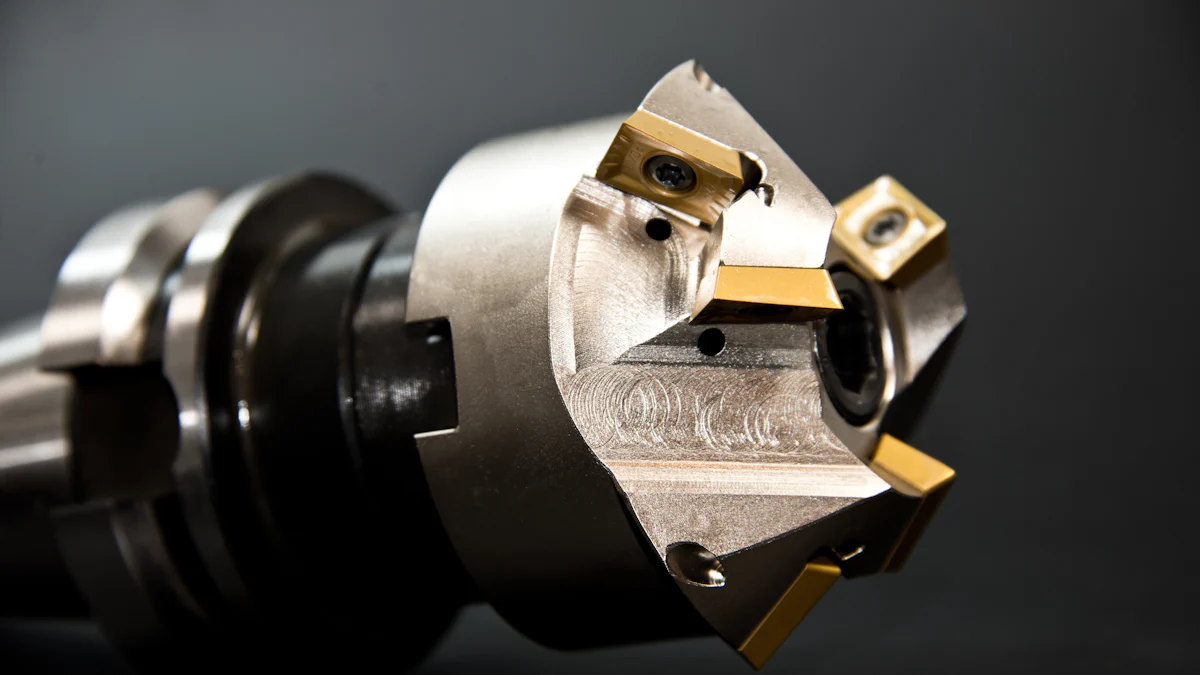

Rotary Cutting Tools

Rotary cutting tools offer dynamic solutions for metalworking tasks, providing speed and effectiveness in machining operations. Here are three prominent types of rotary cutting tools:

Drill Bits

Drill bits are versatile tools used for creating holes in various materials such as metal, wood, and plastic. Premium drill bits offer enhanced durability and precision, making them ideal for demanding drilling applications. With advanced coatings and designs, these cutting tools deliver efficient hole-making capabilities.

Taps

Taps are essential for creating internal threads in drilled holes, enabling the assembly of threaded fasteners securely. Premium taps feature high wear resistance and sharp cutting edges, ensuring smooth thread production without compromising strength. By using quality taps, manufacturers can streamline threading processes effectively.

Saw Blades

Saw blades are indispensable tools for cutting through different materials with precision and speed. Premium saw blades exhibit superior tooth design and material composition for efficient material removal while maintaining accuracy. Whether it’s cross-cutting or rip-cutting tasks, these cutting tools provide reliable performance in diverse woodworking applications.

Choosing the Right Cutting Tool

Assessing Material

To select the most suitable cutting tool for a specific task, it is crucial to assess the material being worked on. Material hardness plays a significant role in determining the type of cutting tool required. Harder materials necessitate tools with greater durability and strength to maintain precision during machining processes. Conversely, softer materials may benefit from tools that provide higher cutting speeds without compromising accuracy.

When considering material type, various factors come into play. Different materials, such as metals, plastics, or composites, require specific cutting tools tailored to their properties. For instance, metals like steel demand robust tools capable of withstanding high temperatures and pressures during cutting. On the other hand, plastics may require tools that reduce friction to prevent melting or deformation.

Application Requirements

Understanding the precision needs of a particular application is essential for choosing the right cutting tool. Some tasks demand intricate detailing and fine finishes, necessitating tools with high precision capabilities. By selecting cutting tools that align with precision requirements, operators can achieve accurate results consistently across various workpieces.

Speed requirements also influence the choice of cutting tool for a given application. Tasks that prioritize efficiency and quick turnaround times benefit from tools designed for high-speed operations. These tools enable rapid material removal while maintaining quality standards, enhancing productivity in metalworking processes.

Recap of the Benefits of Premium Cutting Tools:

- Enhanced precision ensures impeccable results.

- Increased efficiency leads to faster operations.

- Cost-effectiveness with long-term savings.

Summary of the Types of Cutting Tools:

- Linear cutting tools like tool bits and broaches.

- Rotary cutting tools including drill bits, taps, and saw blades.

Final Thoughts on Choosing the Right Cutting Tool:

Select tools based on material hardness and application requirements for optimal performance.

Potential Future Developments in Cutting Tool Technology:

Continuous advancements aim to enhance precision and efficiency in metalworking processes.