Wire rope cutting tools play a crucial role in various industries. Construction, marine, and mining sectors rely on these tools for precision and efficiency. Recent advancements have revolutionized wire rope cutters. The use of advanced materials and precision cutting mechanisms enhances performance and reliability. Selecting the right tool ensures optimal results for specific applications. The right choice increases efficiency and reduces operational costs. Investing in the best wire rope cutting tools offers long-term benefits. Make informed decisions to enhance productivity and safety.

Types of Wire Rope Cutting Tools

Choosing the right wire rope cutting tools can significantly impact your work efficiency and safety. Each type of cutter offers unique features and benefits tailored to specific applications. Understanding these differences will help you make an informed decision.

Manual Wire Rope Cutters

Features and Benefits

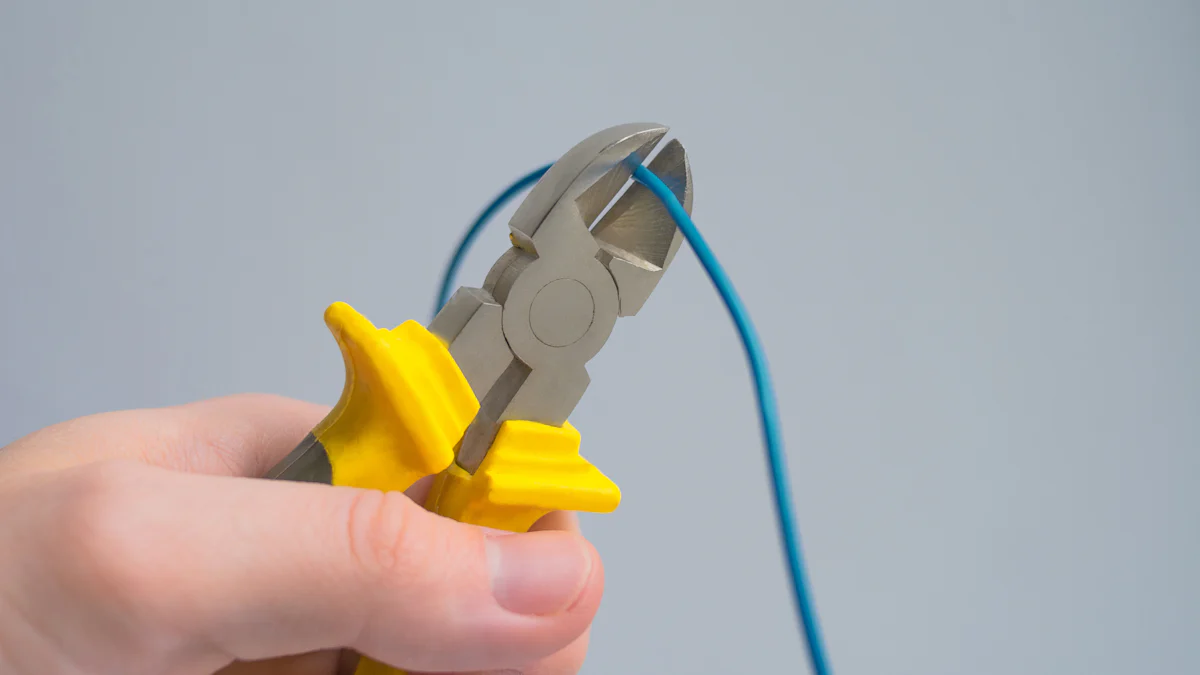

Manual wire rope cutters provide a straightforward solution for cutting wire ropes. These tools offer precision and control, making them ideal for smaller projects. The compact design allows for easy handling and storage. Many manual cutters feature hardened steel blades that ensure clean cuts without fraying. Users appreciate the reliability and durability of these tools in various settings.

Best Use Cases

Manual wire rope cutters excel in situations where portability and ease of use are crucial. These tools are perfect for DIY enthusiasts and professionals working on small-scale projects. You can use them effectively in construction, marine, and utility applications. The simplicity of manual cutters makes them a go-to choice for quick and precise cuts.

Hydraulic Wire Rope Cutters

Features and Benefits

Hydraulic wire rope cutters are designed for heavy-duty applications. These tools provide immense cutting power with minimal effort. The hydraulic mechanism ensures smooth and efficient cuts through thick wire ropes. Users benefit from the increased leverage and precision offered by hydraulic cutters. Durability is a hallmark of these tools, making them a long-term investment.

Best Use Cases

Hydraulic wire rope cutters are indispensable in industries like construction, mining, and marine. These tools handle large-diameter wire ropes with ease. Professionals rely on hydraulic cutters for tasks requiring high precision and strength. The ability to cut through tough materials makes them essential for challenging projects.

Electric Wire Rope Cutters

Features and Benefits

Electric wire rope cutters combine power and convenience. These tools offer rapid cutting speeds and consistent performance. The electric motor reduces manual effort, allowing for effortless operation. Users enjoy the versatility and efficiency of electric cutters in various environments. Many models come with safety features to prevent accidents during use.

Best Use Cases

Electric wire rope cutters are suitable for frequent and repetitive cutting tasks. These tools shine in industrial settings where speed and efficiency are paramount. You can use electric cutters in workshops, factories, and large-scale construction sites. The blend of power and precision makes them a preferred choice for professionals seeking optimal results.

Factors to Consider When Choosing a Wire Rope Cutter

Choosing the right wire rope cutting tools involves several critical factors. Each factor ensures that you select a tool that meets your specific needs and enhances your work efficiency.

Material and Diameter of Wire Rope

Importance of Compatibility

The material and diameter of the wire rope significantly influence the choice of cutting tools. Different materials require different cutting capacities. A cutter must match the wire rope’s specifications to ensure clean and precise cuts. Incompatible tools may damage the wire rope or the cutter itself. Always check the manufacturer’s guidelines for compatibility. This step prevents unnecessary wear and tear on your equipment.

Frequency of Use

Durability and Longevity

Consider how often you will use the wire rope cutting tools. Frequent use demands a durable and robust tool. Heavy-duty cutters withstand regular usage without compromising performance. Investing in a high-quality tool saves money in the long run. Durable tools reduce the need for frequent replacements. Look for features like hardened steel blades and ergonomic designs. These features enhance both durability and user comfort.

Budget Considerations

Balancing Cost and Quality

Budget plays a crucial role in selecting wire rope cutting tools. However, focusing solely on price can lead to poor choices. Balance cost with quality to get the best value for your investment. High-quality tools may have a higher upfront cost but offer better performance and longevity. Cheaper tools might save money initially but could incur higher costs due to frequent replacements or repairs. Evaluate the tool’s features, brand reputation, and customer reviews. These factors help in making an informed purchasing decision.

Reviews of Top Wire Rope Cutting Tools for 2024

Felco C7 Wire Rope Cutter

Key Features

The Felco C7 Wire Rope Cutter stands out as a top choice among wire rope cutting tools. This Swiss-designed tool boasts exceptional versatility and durability. The high-quality construction ensures that the cutter handles heavy-duty tasks with ease. A sharp cutting edge delivers clean and precise cuts every time. The Felco C7 is suitable for steel wire ropes and stainless steel cables. Industries such as construction, marine, and aviation rely on this tool for its performance.

User Reviews

Users consistently praise the Felco C7 for its reliability and efficiency. Many professionals highlight the cutter’s ability to maintain sharpness over time. The ergonomic design receives positive feedback for comfort during extended use. Customers appreciate the precision and clean cuts achieved with the Felco C7. The tool’s durability makes it a worthwhile investment for various applications.

Knipex 95 61 190 SBA Wire Rope Cutter

Key Features

The Knipex 95 61 190 SBA Wire Rope Cutter offers impressive efficiency in cutting wire ropes. This tool features hardened steel blades that ensure long-lasting sharpness. The compact design allows for easy handling and storage. Users benefit from the cutter’s ability to deliver precise cuts without fraying. The Knipex cutter excels in both professional and DIY settings.

User Reviews

Customers commend the Knipex 95 61 190 SBA for its ease of use and effectiveness. Many users note the cutter’s ability to handle various wire rope sizes with precision. The lightweight design receives positive remarks for reducing user fatigue. Reviews often mention the tool’s durability and consistent performance. The Knipex cutter remains a popular choice for those seeking reliable wire rope cutting tools.

MCC Professional Tools Compound Leverage Wire Rope Cutter

Key Features

The MCC Professional Tools Compound Leverage Wire Rope Cutter minimizes cutting effort with its innovative design. The compound leverage mechanism provides increased cutting power. This feature makes the tool ideal for tough wire materials. The cutter’s robust construction ensures longevity and reliability. Users find the MCC cutter effective for both small and large wire ropes.

User Reviews

Professionals appreciate the MCC cutter’s ability to handle demanding tasks with ease. The tool’s design receives praise for reducing the physical effort required during use. Many users highlight the cutter’s durability and consistent performance. The MCC cutter’s ability to deliver clean cuts enhances its reputation among wire rope cutting tools. Customers recommend this tool for its efficiency and strength.

Pros and Cons of Wire Rope Cutting Tools

Advantages

Efficiency and Precision

Wire rope cutting tools offer unmatched efficiency in various applications. These tools cut wire ropes quickly, reducing labor costs and time. Professionals rely on these cutters for their precision. Clean cuts prevent fraying, ensuring the integrity of the wire rope. The design of each tool enhances user control and accuracy. Hydraulic and electric cutters provide immense power with minimal effort. Manual cutters excel in portability and ease of use. Each type of cutter meets specific needs, enhancing overall work efficiency.

Disadvantages

Potential Limitations

Despite their benefits, wire rope cutting tools have limitations. Heavy-duty cutters may struggle with certain wire materials. Technological advancements improve performance but do not eliminate all challenges. Manual cutters require physical effort, which can lead to fatigue. Hydraulic systems need regular maintenance to ensure optimal performance. Electric cutters depend on power sources, limiting their portability. Users must consider these factors when selecting a tool. Proper selection ensures that the tool meets the demands of the task at hand.

Maintenance Tips for Wire Rope Cutting Tools

Proper maintenance ensures wire rope cutting tools perform efficiently and last longer. Regular care prevents damage and enhances safety during use. Follow these tips to keep your tools in top condition.

Regular Cleaning and Lubrication

Steps to Follow

Regular cleaning removes debris that can affect cutting efficiency. Use a soft brush to clean the blades after each use. Ensure no residue remains on the cutting edge. Apply oil to the hinge regularly for smooth operation. Lubrication reduces friction and prevents rust. Sharp blades ensure precise cuts, so sharpen them with a whetstone if needed. Follow the manufacturer’s guidelines for specific maintenance instructions. Proper care guarantees optimal performance and extends tool life.

Proper Storage

Best Practices

Store wire rope cutting tools in a dry place to prevent rust. Use a protective case or cover to shield the blades. Avoid placing heavy objects on top of stored tools. Proper storage maintains blade sharpness and tool integrity. Organize tools neatly to prevent accidents. Label storage areas for easy identification and access. Follow these best practices to ensure your tools remain in excellent condition.

Selecting the right wire rope cutting tool is crucial for achieving precision and efficiency in your projects. The reviewed tools, including the Felco C7, Knipex 95 61 190 SBA, and MCC Professional Tools Compound Leverage Cutter, offer distinct advantages for various applications. Investing in high-quality cutters enhances safety and productivity. Consider factors like material compatibility, frequency of use, and budget when making a purchase decision.

FAQs:

- What factors should guide the selection of a wire rope cutter?

- How do manual and hydraulic cutters differ in use?

- What maintenance practices ensure tool longevity?