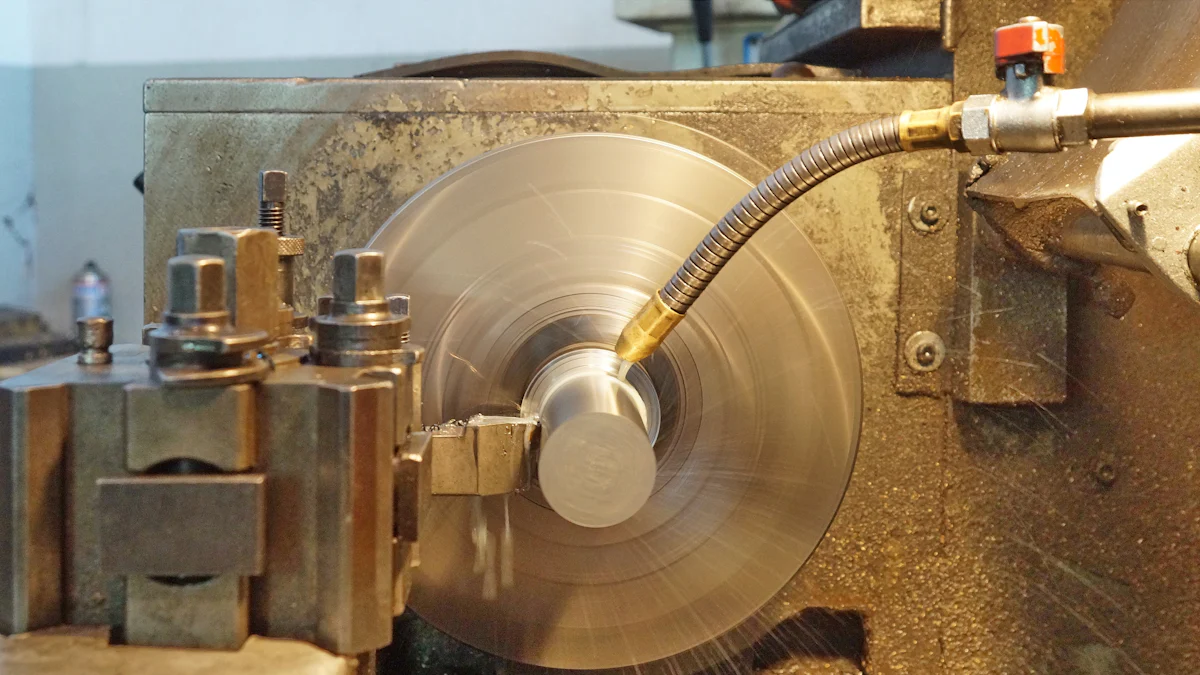

Precision cutting holds paramount importance in machining. The lathe cut off tool plays a crucial role in achieving this precision. High accuracy levels in CNC machining drive demand from the electronics manufacturing sector. Enhanced efficiency and cost savings in batch production make these tools indispensable. Modern statistical process control (SPC) improves quality and reliability, reducing operating costs. This blog will explore the top 10 lathe cut off tools that ensure superior performance and precision.

Understanding Lathe Cut Off Tools

What are Lathe Cut Off Tools?

Definition and Purpose

A lathe cut off tool serves a critical function in machining. This tool separates a finished part from the remaining material. Precision cutting ensures high-quality results. Machinists rely on these tools for accurate and efficient operations.

Common Materials Used

Manufacturers use various materials to produce lathe cut off tools. High-speed steel (HSS) offers durability and sharpness. Carbide provides superior hardness and wear resistance. Ceramic materials excel in high-temperature applications. Each material suits different machining needs.

Key Features to Look For

Material Quality

Material quality significantly impacts performance. High-speed steel offers excellent toughness. Carbide ensures longer tool life. Ceramic materials withstand extreme conditions. Choosing the right material enhances cutting efficiency.

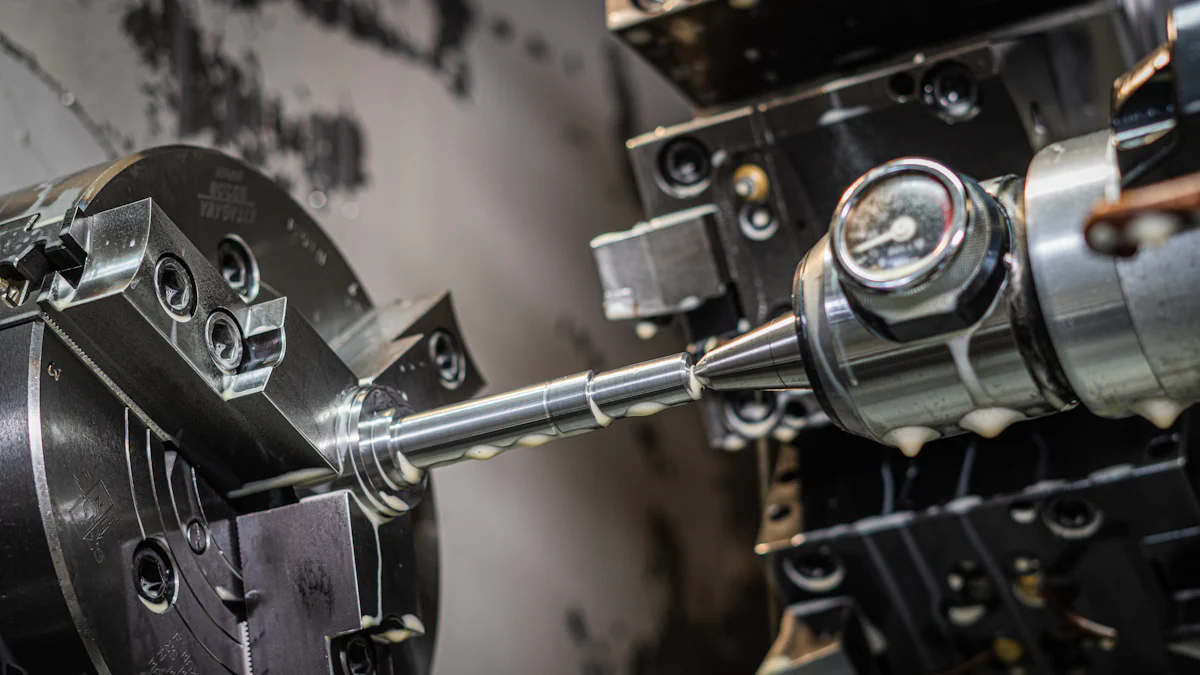

Cutting Edge Design

Cutting edge design determines the effectiveness of a lathe cut off tool. A sharp edge reduces cutting force. A well-designed rake angle improves chip evacuation. Proper geometry minimizes tool wear. These factors contribute to precise and smooth cuts.

Durability and Longevity

Durability and longevity are essential for cost-effective machining. High-quality materials extend tool life. Proper heat treatment enhances strength. Regular maintenance prevents premature wear. Investing in durable tools reduces downtime and increases productivity.

Top 10 Lathe Cut Off Tools

Tool 1: Iscar Tangrip

Features

The Iscar Tangrip features a robust design with a unique tangential clamping mechanism. This design ensures secure and stable tool placement. The tool uses high-quality carbide inserts that provide excellent wear resistance. The cutting edge geometry minimizes vibration during operations.

Benefits

The Iscar Tangrip offers superior precision in cutting. The tangential clamping mechanism enhances stability, reducing the risk of tool displacement. The carbide inserts extend tool life, reducing the frequency of replacements. The minimized vibration results in smoother cuts and improved surface finishes.

Ideal Applications

The Iscar Tangrip excels in high-precision machining tasks. It is ideal for applications requiring tight tolerances and fine surface finishes. This tool performs exceptionally well in both small and large batch productions.

Tool 2: Manchester Parting Tool

Features

The Manchester Parting Tool boasts versatility with its adaptable design. The tool features high-speed steel construction, providing a balance between toughness and sharpness. The cutting edge incorporates a specific rake angle to facilitate efficient chip evacuation.

Benefits

The Manchester Parting Tool delivers consistent performance across various materials. The high-speed steel construction ensures durability and sharpness. The efficient chip evacuation reduces heat buildup, prolonging tool life. The versatile design allows use in multiple cutting operations.

Ideal Applications

The Manchester Parting Tool is suitable for general-purpose machining. It handles a wide range of materials, making it ideal for workshops with diverse machining needs. This tool is perfect for creating intricate details like fillets, beads, and spigots.

Tool 3: Bluefox Tools Lathe Adjustable Type Parting Cut Off Tool Holder

Features

The Bluefox Tools Lathe Adjustable Type Parting Cut Off Tool Holder features an adjustable design for flexibility. The tool holder accommodates various blade sizes, enhancing its versatility. The robust construction ensures stability during cutting operations.

Benefits

The Bluefox Tools Lathe Adjustable Type Parting Cut Off Tool Holder offers adaptability for different cutting tasks. The adjustable design allows quick changes between blade sizes, increasing efficiency. The stable construction reduces vibration, resulting in precise cuts.

Ideal Applications

The Bluefox Tools Lathe Adjustable Type Parting Cut Off Tool Holder is ideal for workshops requiring flexibility. It suits both small-scale and large-scale productions. This tool holder is perfect for machinists who frequently switch between different cutting tasks.

Tool 4: Benjamin’s Best High Speed Steel 3/4″ x 1/8″ Parting Tool

Features

Benjamin’s Best High Speed Steel 3/4″ x 1/8″ Parting Tool features a high-speed steel construction. This material offers excellent toughness and sharpness. The tool has a diamond cross-section that reduces friction and heat buildup. The design ensures precise cuts and smooth finishes.

Benefits

Benjamin’s Best High Speed Steel 3/4″ x 1/8″ Parting Tool provides superior control during cutting operations. The reduced friction minimizes heat buildup, preventing cracks in hardwoods. The high-speed steel construction ensures durability and longevity. The tool delivers precise cuts, enhancing the quality of the finished product.

Ideal Applications

Benjamin’s Best High Speed Steel 3/4″ x 1/8″ Parting Tool is ideal for cutting tenons and establishing diameters. The tool excels in creating small flat areas and intricate details. Machinists can rely on this lathe cut off tool for both spindle workpieces and general parting tasks.

Tool 5: Kennametal Evo System with ECO30M03N00CF02 Inserts

Features

Kennametal Evo System with ECO30M03N00CF02 Inserts features a modular design. The system uses high-quality carbide inserts. These inserts provide excellent wear resistance and cutting performance. The tool’s design ensures stable and secure placement during operations.

Benefits

Kennametal Evo System with ECO30M03N00CF02 Inserts offers enhanced precision in cutting. The carbide inserts extend tool life, reducing the need for frequent replacements. The modular design allows quick and easy insert changes. The stable placement minimizes vibration, resulting in smoother cuts.

Ideal Applications

Kennametal Evo System with ECO30M03N00CF02 Inserts is perfect for high-precision machining tasks. The tool performs exceptionally well in CNC lathe operations. Machinists can use this lathe cut off tool for various materials, including metals and alloys.

Tool 6: Busy Bee Tools Cut Off and Parting Tools

Features

Busy Bee Tools Cut Off and Parting Tools feature robust construction. The tools use high-speed steel and carbide materials. The design includes specific rake angles for efficient chip evacuation. The tools offer versatility for different cutting tasks.

Benefits

Busy Bee Tools Cut Off and Parting Tools provide consistent performance across various materials. The high-speed steel and carbide construction ensure durability and sharpness. The efficient chip evacuation reduces heat buildup, prolonging tool life. The versatile design allows use in multiple cutting operations.

Ideal Applications

Busy Bee Tools Cut Off and Parting Tools are suitable for general-purpose machining. The tools handle a wide range of materials, making them ideal for workshops with diverse needs. Machinists can rely on these lathe cut off tools for both small-scale and large-scale productions.

Tool 7: McMaster-Carr Indexable Lathe Tools

Features

McMaster-Carr Indexable Lathe Tools feature a modular design. The tools use high-quality carbide inserts. These inserts provide excellent wear resistance and cutting performance. The tool holders ensure stable and secure placement during operations.

Benefits

McMaster-Carr Indexable Lathe Tools offer enhanced precision in cutting. The carbide inserts extend tool life, reducing the need for frequent replacements. The modular design allows quick and easy insert changes. The stable placement minimizes vibration, resulting in smoother cuts.

Ideal Applications

McMaster-Carr Indexable Lathe Tools are perfect for high-precision machining tasks. The tools perform exceptionally well in CNC lathe operations. Machinists can use these lathe cut off tools for various materials, including metals and alloys.

Tool 8: Accusize Industrial Tools Carbide Parting Tool

Features

Accusize Industrial Tools Carbide Parting Tool features a robust carbide construction. The tool includes a specific rake angle for efficient chip evacuation. The design ensures precise cuts and smooth finishes.

Benefits

Accusize Industrial Tools Carbide Parting Tool provides superior control during cutting operations. The efficient chip evacuation reduces heat buildup, prolonging tool life. The carbide construction ensures durability and sharpness. The tool delivers precise cuts, enhancing the quality of the finished product.

Ideal Applications

Accusize Industrial Tools Carbide Parting Tool is ideal for general-purpose machining. The tool handles a wide range of materials, making it perfect for workshops with diverse needs. Machinists can rely on this lathe cut off tool for both small-scale and large-scale productions.

Tool 9: Sandvik Coromant Parting and Grooving Tool

Features

Sandvik Coromant Parting and Grooving Tool features a high-speed steel construction. The tool incorporates a unique edge design for reduced cutting forces. The design ensures stability and precision during operations.

Benefits

Sandvik Coromant Parting and Grooving Tool offers exceptional performance in cutting. The reduced cutting forces minimize tool wear, extending tool life. The high-speed steel construction provides toughness and sharpness. The tool delivers smooth and accurate cuts, improving surface finishes.

Ideal Applications

Sandvik Coromant Parting and Grooving Tool is suitable for high-precision machining tasks. The tool excels in creating intricate details like fillets, beads, and spigots. Machinists can use this lathe cut off tool for various materials, including metals and alloys.

Tool 10: [Additional Tool Name]

Features

The Accusize Industrial Tools Carbide Parting Tool features a robust carbide construction. The tool includes a specific rake angle for efficient chip evacuation. The design ensures precise cuts and smooth finishes.

Benefits

The Accusize Industrial Tools Carbide Parting Tool provides superior control during cutting operations. The efficient chip evacuation reduces heat buildup, prolonging tool life. The carbide construction ensures durability and sharpness. The tool delivers precise cuts, enhancing the quality of the finished product.

Ideal Applications

The Accusize Industrial Tools Carbide Parting Tool is ideal for general-purpose machining. The tool handles a wide range of materials, making it perfect for workshops with diverse needs. Machinists can rely on this lathe cut off tool for both small-scale and large-scale productions.

How to Choose the Right Lathe Cut Off Tool

Assessing Your Needs

Type of Material Being Cut

Selecting the appropriate lathe cut off tool begins with understanding the type of material being cut. Different materials require specific tools for optimal performance. High-speed steel tools work well for softer materials like aluminum and brass. Carbide tools excel in cutting harder materials such as stainless steel and cast iron. Ceramic tools perform best in high-temperature applications. Matching the tool material to the workpiece material ensures efficient cutting and prolongs tool life.

Desired Precision Level

Precision levels vary depending on the machining task. For tasks requiring high accuracy, choose a lathe cut off tool with a sharp cutting edge and precise geometry. Tools like Benjamin’s Best HSS Lathe Tennon Tool offer precise cuts for smooth finishes. For general-purpose machining, tools with moderate precision levels suffice. Assessing the desired precision level helps in selecting a tool that meets specific machining requirements.

Budget Considerations

Cost vs. Quality

Balancing cost and quality is crucial when choosing a lathe cut off tool. High-quality tools often come with a higher price tag but offer better performance and longevity. Investing in tools made from durable materials like carbide or high-speed steel can reduce long-term costs. Cheaper tools may save money initially but could wear out quickly, leading to frequent replacements. Prioritizing quality over cost ensures better value and efficiency in the long run.

Long-Term Investment

Consider lathe cut off tools as long-term investments. High-quality tools like Kennametal Evo System with ECO30M03N00CF02 Inserts provide extended tool life and consistent performance. Investing in durable tools reduces downtime and maintenance costs. Long-term investments in quality tools enhance productivity and precision in machining operations.

User Reviews and Recommendations

Importance of Reviews

User reviews offer valuable insights into the performance and reliability of lathe cut off tools. Reviews highlight real-world experiences and potential issues with specific tools. Positive reviews indicate satisfaction and effectiveness, while negative reviews reveal common problems. Considering user feedback helps in making informed decisions.

Where to Find Reliable Reviews

Reliable reviews can be found on various platforms. Online marketplaces like Amazon feature customer reviews for products like Bluefox Tools Lathe Adjustable Type Parting Cut Off Tool Holder. Industry forums and websites dedicated to machining provide expert opinions and user experiences. Manufacturer websites often include testimonials and case studies. Consulting multiple sources ensures a comprehensive understanding of the tool’s performance.

Choosing the right lathe cut off tool is crucial for achieving precision in machining. The top 10 tools discussed offer various features and benefits tailored to different needs. Investing in high-quality tools like the Iscar Tangrip or Kennametal Evo System ensures superior performance and longevity. Machinists should prioritize durable materials and efficient designs to enhance productivity. Quality tools not only improve accuracy but also reduce downtime and maintenance costs. For better precision and efficiency, investing in reliable lathe cut off tools is essential.

See Also

Scooter Upgrades: High-Quality Parts for Optimal Performance

Discovering Diverse Sock Options for Both Genders

Mastering Winter Comfort with Soft and Cozy Towel Socks