Choosing the right air tools is crucial for efficiency and productivity. Ace hardware air tools offer a wide range of options to suit various needs. Several factors influence the decision, including power output, size, and weight. Understanding these factors ensures the selection of tools that match specific requirements. The right tools enhance performance and safety in both DIY and professional settings.

Understanding Air Tool Specifications

PSI and CFM Requirements

What is PSI?

PSI, or Pounds per Square Inch, measures the air pressure delivered by an air compressor. Ace hardware air tools typically require around 90 to 100 PSI for optimal performance. Ensuring the correct PSI ensures that the tool operates efficiently and delivers the expected power output.

What is CFM?

CFM, or Cubic Feet per Minute, represents the volume of air an air tool consumes. Ace hardware air tools need a specific CFM to function correctly. For instance, light-duty tools may require 0 to 5 CFM at 70 to 90 PSI, while more demanding tools might need over 10 CFM at 100 to 120 PSI.

How to Determine the Right PSI and CFM for Your Needs

To determine the appropriate PSI and CFM, consider the most demanding tool you plan to use. Match the tool’s requirements with the air compressor’s output. For example, if using multiple ace hardware air tools simultaneously, add up the PSI ratings to ensure the compressor can handle the combined load. This approach prevents performance issues and tool damage.

Compatibility with Air Compressors

Matching Air Tools with Your Compressor

Matching ace hardware air tools with your air compressor involves ensuring the compressor can provide the required PSI and CFM. A mismatch can lead to subpar performance and potential tool damage. Most air compressors are rated at 90 PSI, suitable for many tools. However, some tools, like framing nailers, may require higher PSI for maximum efficiency.

Common Compatibility Issues and Solutions

Common compatibility issues include insufficient air pressure and inadequate air supply. To resolve these issues, ensure the air compressor meets the PSI and CFM requirements of your ace hardware air tools. Additionally, consider the size of the air compressor tank, as a larger tank provides a steady flow of compressed air, preventing interruptions during operation.

Operational Environment

Indoor vs. Outdoor Use

The operational environment significantly impacts the performance of ace hardware air tools. Indoor use typically requires less robust tools compared to outdoor use. Consider the workspace and ensure the tools are suitable for the environment to avoid performance issues.

Temperature and Humidity Considerations

Temperature and humidity affect the efficiency of ace hardware air tools. High humidity can cause moisture buildup, leading to rust and reduced tool lifespan. Extreme temperatures can also impact tool performance. Ensure proper maintenance and storage to mitigate these effects and prolong the life of your tools.

Key Features to Consider

Safety Features

Built-in safety mechanisms

Ace hardware air tools come equipped with various built-in safety mechanisms. These features include over-pressure protection and low-oil shutdown. Over-pressure protection prevents the tool from operating at unsafe pressure levels. Low-oil shutdown ensures the tool turns off when oil levels are too low, preventing damage.

Personal protective equipment (PPE) recommendations

Using ace hardware air tools requires proper personal protective equipment (PPE). Essential PPE includes safety glasses, ear protection, and gloves. Safety glasses protect eyes from flying debris. Ear protection reduces the risk of hearing damage from loud tool operation. Gloves provide a better grip and protect hands from sharp edges and vibrations.

Ergonomics

Importance of ergonomic design

Ergonomic design in ace hardware air tools enhances user comfort and reduces fatigue. Proper ergonomics improve efficiency and safety. Tools with poor ergonomic design can lead to strain injuries and decreased productivity.

Features to look for in ergonomic air tools

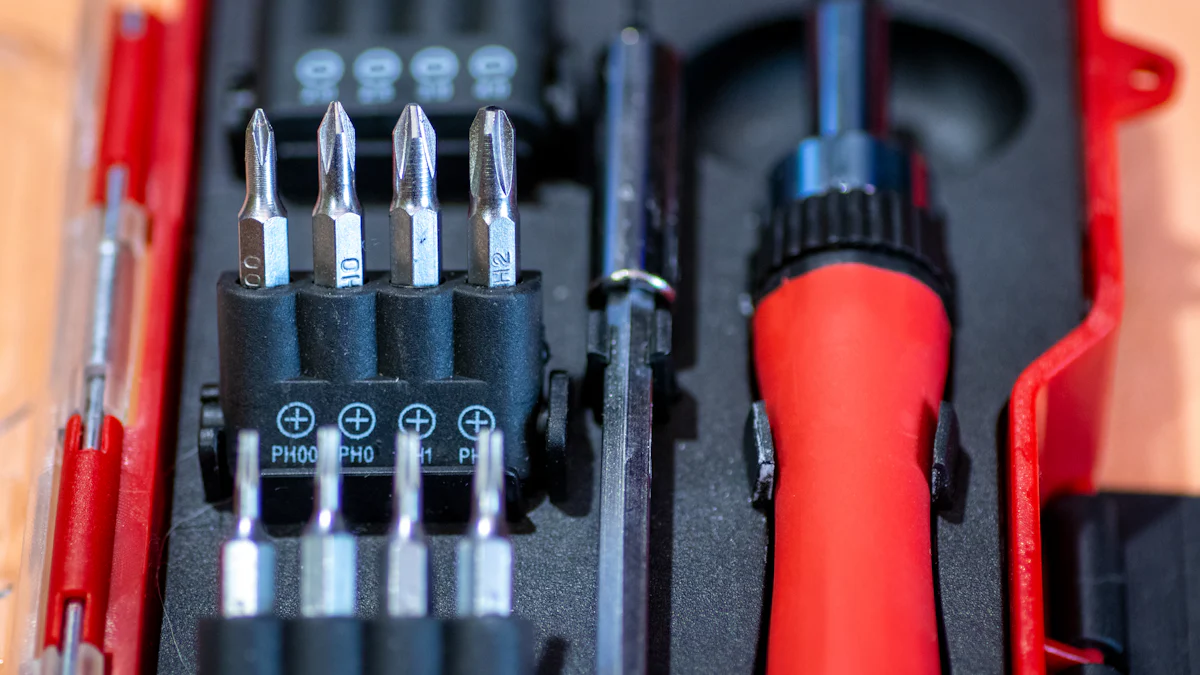

When selecting ace hardware air tools, look for features that enhance ergonomics. Lightweight materials reduce user fatigue. Rubberized grips provide a secure hold and minimize vibrations. Balanced weight distribution ensures ease of use over extended periods. These features contribute to a safer and more comfortable working experience.

Maintenance

Routine maintenance tasks

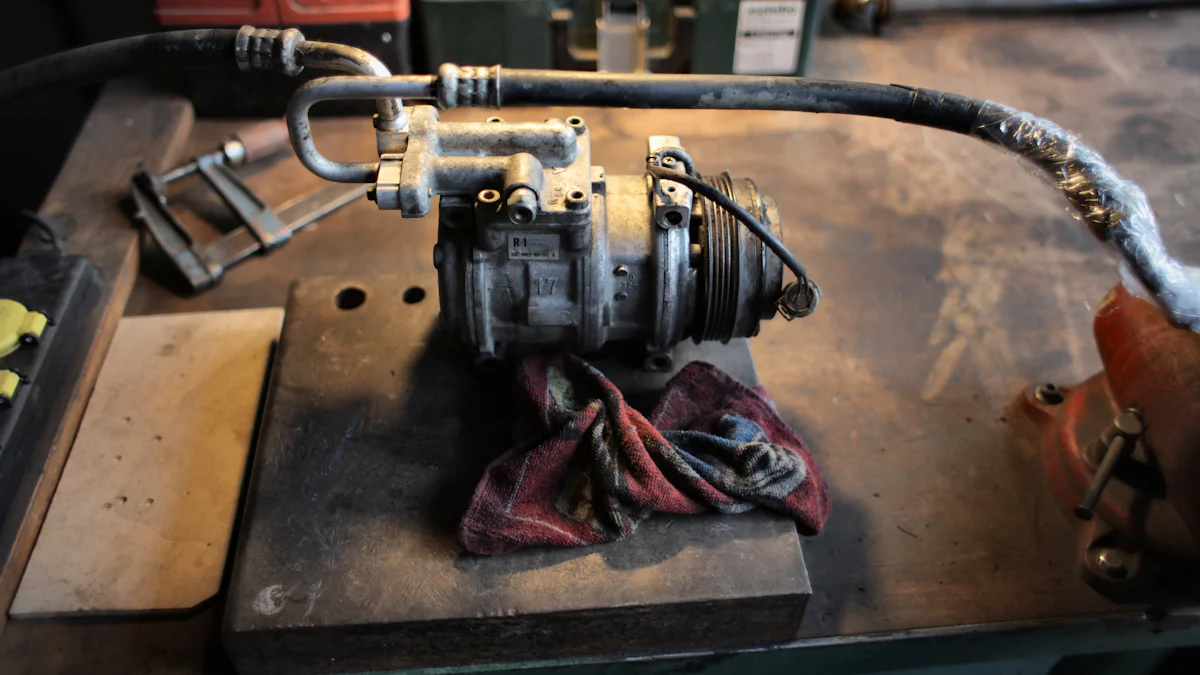

Routine maintenance keeps ace hardware air tools in optimal condition. Regularly check for wear and tear on moving parts. Lubricate components to ensure smooth operation. Inspect air hoses for leaks and replace them if necessary. Clean the tools after each use to prevent dirt buildup.

Tips for prolonging the life of your air tools

Prolong the life of ace hardware air tools by following some simple tips. Store tools in a dry, cool place to prevent rust. Use an air filter to keep dirt and debris out of the tool’s internal components. Regularly check and maintain the air compressor to ensure it provides consistent pressure and airflow. Following these tips will help maintain tool performance and extend their lifespan.

Recommendations for Different Users

DIY Enthusiasts

Essential Air Tools for Home Projects

DIY enthusiasts often require versatile and user-friendly air tools. Essential tools include:

- Air Compressor: A compact model with a 90 PSI rating suits most home projects.

- Impact Wrench: Ideal for automotive repairs and heavy-duty tasks.

- Air Ratchet: Useful for tightening and loosening bolts in tight spaces.

- Nail Gun: Perfect for woodworking and home improvement projects.

These tools enhance efficiency and make home projects more manageable.

Budget-Friendly Options

Budget constraints often influence tool selection for DIY enthusiasts. Affordable yet reliable options include:

- Campbell Hausfeld: Known for cost-effective and durable air tools.

- Bostitch: Offers budget-friendly nail guns and compressors.

- Central Pneumatic: Provides a range of affordable air tools suitable for various tasks.

Choosing budget-friendly brands ensures quality without overspending.

Professionals

High-Performance Air Tools for Demanding Tasks

Professionals require high-performance air tools to handle demanding tasks. Recommended tools include:

- Ingersoll Rand Impact Wrench: Renowned for its power and durability.

- Chicago Pneumatic Air Ratchet: Offers excellent torque and reliability.

- Shinano Die Grinder: Known for precision and longevity.

These tools meet the rigorous demands of professional use.

Investing in Quality and Durability

Investing in high-quality air tools ensures long-term reliability and performance. Key considerations include:

- Brand Reputation: Renowned brands like Ingersoll Rand, AirCat, and Shinano offer reliable and durable tools.

- Build Quality: High-quality materials and construction extend tool lifespan.

- Maintenance: Regular cleaning and proper lubrication enhance tool longevity.

“Well-maintained and high-quality air tools can last for many years of regular use.” – User Testimonial

Investing in premium brands and maintaining tools properly ensures optimal performance and durability.

Selecting the right air tools involves understanding specifications and matching them to specific needs. Key considerations include PSI, CFM, compatibility with compressors, and operational environment. Safety features, ergonomic design, and maintenance also play crucial roles.

Final Recommendations:

- DIY Enthusiasts:

- Opt for budget-friendly brands like Campbell Hausfeld and Bostitch.

- Essential tools include a compact air compressor, impact wrench, air ratchet, and nail gun.

- Professionals:

- Invest in high-performance brands such as Ingersoll Rand and Chicago Pneumatic.

- Focus on tools with excellent torque, precision, and durability.

“Quality air tools enhance efficiency and achieve professional results.” – Seasoned professionals

Make informed decisions by considering task requirements and maintaining tools properly. High-quality air tools ensure long-term reliability and optimal performance.

See Also

Discovering the Range of Socks for Males and Females

Top Tips for Warm Winter with Soft Cozy Sock Towels