Mastering Hand Grinding Tools

Understanding Surface Grinding

When it comes to achieving smooth and precise surfaces, hand grinding tools play a crucial role. These versatile tools are essential for various surface finishing tasks, offering manual control and precision. From smoothing metal surfaces to refining concrete and stone, hand-held grinding tools are indispensable for achieving the desired results. Mastering the effective use of these manual grinding tools is essential for ensuring superior surface grinding results across different materials and applications.

Understanding Surface Grinding

Surface Grinding Techniques

Surface grinding is a fundamental process for achieving smooth and precise surfaces on various materials. This technique involves the use of hand grinding tools to remove small amounts of material from a workpiece’s surface, resulting in a smooth and flat finish. The importance of surface grinding cannot be overstated, as it is essential for achieving the desired surface quality and dimensional accuracy.

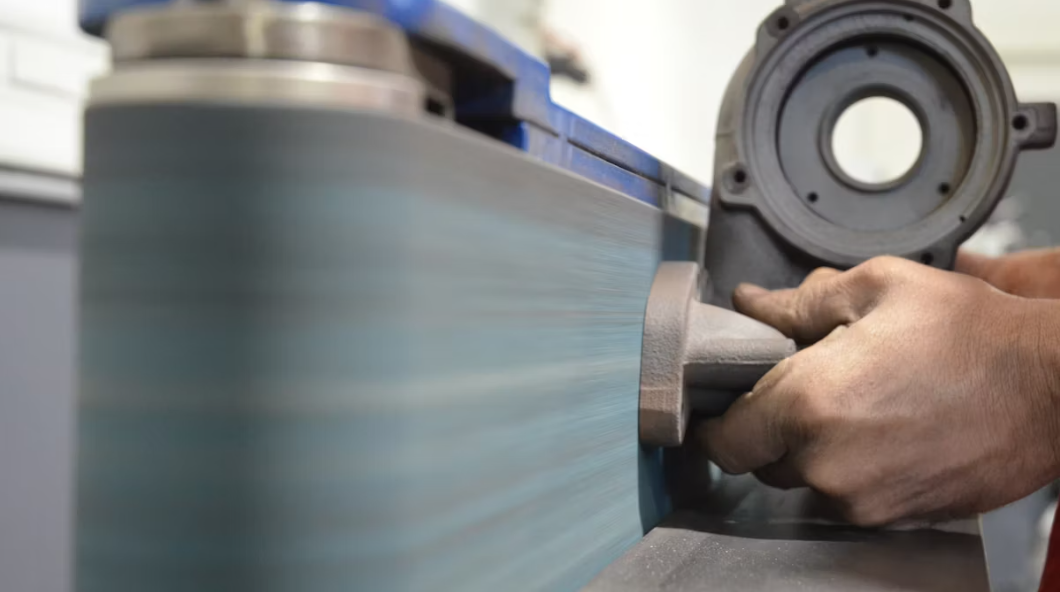

The process of surface grinding typically begins with securing the workpiece to a worktable using clamps or other holding devices. The grinding wheel is then brought into contact with the workpiece, and an abrasive material removes small chips of material to create the desired surface finish. This method allows for tight tolerances and exceptional surface finishes, making it an indispensable technique in manufacturing and metalworking.

Applications of Surface Grinding

Surface grinding finds extensive applications in various industries, including metalworking, construction, and fabrication. It is commonly used for precision grinding of metal surfaces, providing a smooth and flat finish that meets stringent quality standards. Additionally, surface grinding is employed for refining concrete and stone surfaces, ensuring uniformity and precision in architectural and construction projects.

The versatility of surface grinding techniques makes them suitable for a wide range of materials, including steel, aluminum, concrete, granite, and more. Whether it’s preparing metal components for assembly or enhancing the aesthetic appeal of architectural elements, surface grinding plays a crucial role in achieving superior results across different applications.

Selecting Abrasive Tools

Types of Abrasive Materials

When it comes to selecting abrasive materials for hand grinding tools, it’s essential to understand the different options available. Abrasive materials are crucial for effectively removing material from the workpiece’s surface during the grinding process. Here are some common types of abrasive materials used in hand grinding tools:

- Aluminum Oxide: This versatile abrasive material is suitable for a wide range of applications and is known for its durability and long lifespan.

- Silicon Carbide: Widely used for grinding non-ferrous metals and non-metallic materials, silicon carbide offers fast stock removal and excellent surface finish.

- Ceramic Aluminum Oxide: Known for its exceptional toughness and precision cutting, ceramic aluminum oxide is ideal for heavy-duty applications and challenging materials.

Choosing the Right Grinding Wheel

Selecting the right grinding wheel is crucial for achieving optimal results in surface grinding. Several factors should be considered when choosing a grinding wheel:

- Material Compatibility: It’s important to match the characteristics of the grinding wheel with the material being worked on to ensure efficient material removal without causing damage.

- Grit Size: The grit size of the abrasive particles on the wheel determines the finish and stock removal rate, with coarser grit sizes providing faster material removal.

- Wheel Hardness: The hardness of the wheel affects its ability to retain sharp cutting edges, making it essential to select a wheel that suits the specific application.

By understanding these factors and selecting appropriate abrasive materials and grinding wheels, operators can optimize their hand grinding tools for superior surface finishing results.

Safety Precautions

Protective Gear and Equipment

Prioritizing safety when using hand grinding tools is paramount to prevent injuries and ensure a secure working environment. Essential protective gear for hand grinding includes safety glasses to shield the eyes from debris, dust masks to protect against inhalation of fine particles, and sturdy gloves to safeguard the hands from abrasive materials and sharp edges. Additionally, ear protection should be worn in environments with high noise levels to prevent hearing damage.

Using safety equipment such as machine guards and adjustable rests can further enhance protection during grinding operations. Machine guards provide a barrier between the operator and the rotating components of the grinding tool, while adjustable rests offer stability and reduce the risk of accidental slips or falls. By utilizing appropriate protective gear and equipment, operators can mitigate potential hazards associated with hand grinding tools.

Workplace Safety Measures

Maintaining a safe work environment is essential for promoting a culture of safety and preventing accidents during hand grinding operations. Implementing safety protocols for hand grinding involves conducting regular equipment inspections to identify any potential hazards or malfunctions. It’s crucial to keep work areas clean and organized, ensuring that there are no obstructions that could lead to tripping or falling.

Furthermore, providing comprehensive training on safe grinding practices and emergency procedures is vital for all personnel involved in hand grinding activities. Emphasizing the importance of proper tool handling techniques and creating awareness about potential risks can significantly reduce the likelihood of accidents. By adhering to workplace safety measures, organizations can prioritize the well-being of their employees while optimizing productivity in hand grinding operations.

Effective Grinding Techniques

Precision Grinding

When it comes to precision grinding, attention to detail and meticulous execution are paramount. Precision grinding involves the use of advanced grinding techniques to achieve extremely tight tolerances and exceptional surface finishes. One of the key grinding methods for precision grinding is using specialized grinding wheels with fine grit sizes, allowing for precise material removal while maintaining dimensional accuracy.

Achieving precision in hand grinding requires a high level of skill and expertise. Operators must possess advanced grinding skills and an in-depth understanding of the material properties to ensure consistent and accurate results. Additionally, employing proper tool handling practices and maintaining a stable work environment are essential for achieving precision in hand grinding operations.

Optimizing Grinding Efficiency

Optimizing grinding efficiency is crucial for maximizing the performance of hand grinding tools and achieving superior results. One effective approach for improving grinding practices is to implement strategic wheel dressing techniques, ensuring that the grinding wheel maintains its sharpness and cutting ability throughout the operation. Furthermore, selecting the appropriate feed rates and optimizing cutting parameters can significantly enhance overall grinding techniques, leading to improved efficiency and productivity.

By focusing on precision grinding and implementing strategies to optimize efficiency, operators can elevate the quality of their surface finishing processes while maximizing the potential of hand grinding tools.

Mastering Hand Grinding Tools

Applying the Knowledge of Hand Grinding Tools

To achieve superior results in surface grinding, it is essential to apply the knowledge and expertise gained in using hand-operated grinding tools. By understanding the nuances of different grinding materials and mastering the techniques for manipulating grinding surfaces, operators can elevate the quality of their surface finishing processes. The ability to adapt manual grinding tools to various materials and applications is a testament to the mastery of surface grinding, enabling precision and consistency in achieving desired surface finishes.

Enhancing Safety and Efficiency in Hand Grinding Operations

Prioritizing safety measures and optimizing efficiency are crucial aspects of mastering hand grinding tools. By implementing comprehensive safety protocols and providing ongoing training on safe grinding practices, organizations can ensure a secure working environment while promoting a culture of safety. Simultaneously, focusing on optimizing surface finishing processes through efficient tool handling and strategic wheel dressing techniques enhances productivity and overall operational efficiency.

Mastering the Art of Surface Grinding for Various Materials

Mastering hand-held grinding tools involves honing the skills necessary to achieve exceptional surface finishes across a wide range of grinding materials. From metal surfaces to concrete and stone, operators must develop a deep understanding of material properties and effective manual grinding techniques tailored to each specific application. This mastery allows for consistent, high-quality results that meet stringent industry standards while showcasing the artistry of surface grinding.