In the realm of metalworking, ISCAR cutting tools stand as a beacon of innovation and precision. Warren Buffett’s admiration for ISCAR is evident in his acquisition, marking it as a pivotal moment in the industry’s history. This blog delves into the realm of ISCAR cutting tools, exploring their unparalleled benefits for metalworkers seeking excellence in their craft.

ISCAR Cutting Tools Overview

Product Range

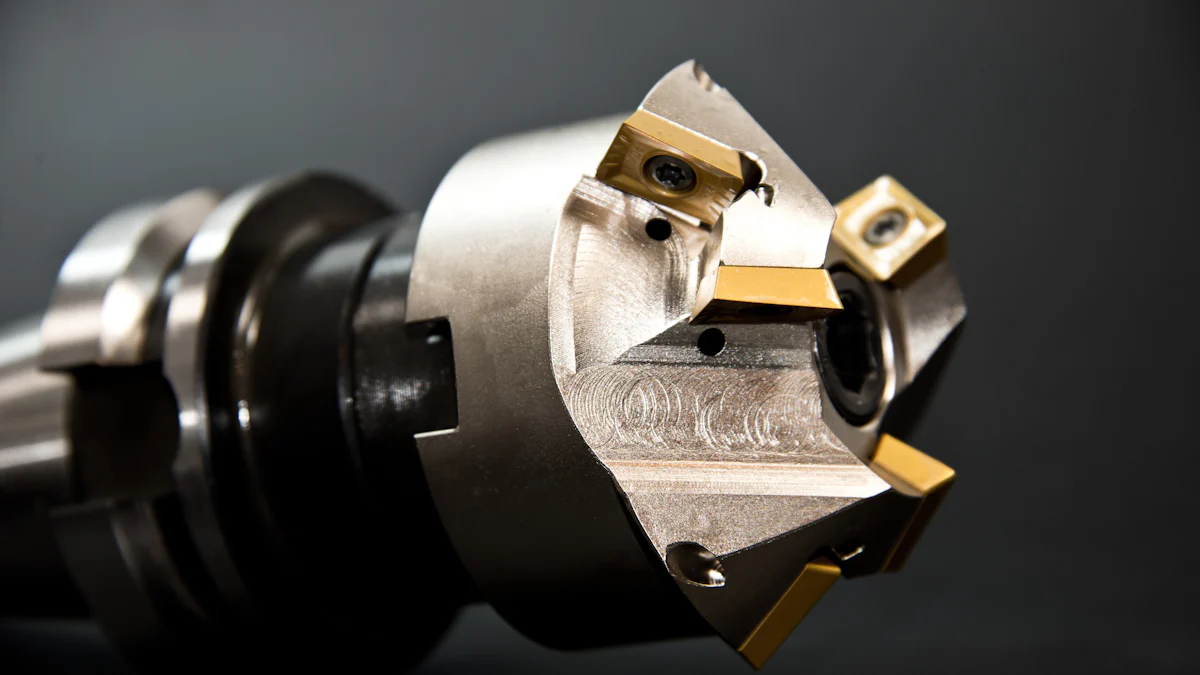

ISCAR, situated in Northern Israel, offers a diverse selection of cutting tools tailored to various metalworking applications. Their product line includes:

- Carbide Inserts: Precision inserts designed for high-performance turning, milling, and drilling.

- End Mills: Specialized end mills for precise and efficient machining operations.

- Drills: High-quality drills suitable for a wide range of materials and cutting conditions.

Technological Advancements

Embracing innovation as a core value, ISCAR constantly pushes the boundaries of cutting tool technology. They have introduced:

- High-Feed Milling (HFM) and High-Speed Machining (HSM) tools to enhance machining capabilities.

- New carbide grades specifically crafted for challenging aerospace materials.

- Extended flute cutters with High-Performance Cutting (HPC) options to boost metal removal rates.

Industry Impact

ISCAR’s cutting tools play a vital role in supporting world-class manufacturing processes across industries like automotive, aerospace, and die & mold production. Their contributions include:

“ISCAR’s precision engineering tools have revolutionized the metalworking industry by meeting the most demanding requirements of modern materials like CFRP and composite materials.”

By providing tailored solutions and advanced tool geometries, ISCAR empowers metalworkers worldwide to achieve unparalleled efficiency and precision in their craft.

Carbide Inserts for Turning

Importance of Carbide Inserts

Carbide inserts play a pivotal role in turning operations, revolutionizing the metalworking industry with their precision and durability. ISCAR’s carbide inserts are specifically engineered to withstand high temperatures and speeds, ensuring optimal performance during cutting processes. The benefits of carbide inserts for turning include:

- Enhanced Durability: Carbide inserts have a longer lifespan compared to traditional cutting tools, reducing the frequency of tool changes and increasing efficiency.

- Improved Precision: The sharp edges of carbide inserts result in precise cuts, leading to higher quality finished products.

- Increased Productivity: With faster cutting speeds and feeds, carbide inserts boost productivity by reducing machining time.

ISCAR’s Carbide Inserts

ISCAR’s dedication to innovation is evident in the design of their carbide inserts for turning. These inserts boast specific features and advantages that set them apart in the industry:

“ISCAR engineers utilize advanced software for simulation of chip formation processes to optimize insert chipformers.”

- Advanced Chipformer Design: ISCAR’s carbide inserts are meticulously crafted using cutting-edge technology, ensuring optimal chip control and evacuation during turning operations.

- Tailored Coatings: The carbide inserts are coated with specialized materials that enhance wear resistance and thermal stability, prolonging tool life.

- Customized Geometries: Each insert is intricately designed with precise geometries to facilitate smooth cutting action and minimize vibrations.

Application Examples

To showcase the versatility and effectiveness of ISCAR’s carbide inserts, consider the following application examples:

Case Studies:

- Aerospace Machining: In aerospace manufacturing, ISCAR’s carbide inserts excel in machining Ni-based superalloys with intricate designs, thanks to their superior heat resistance.

- Automotive Production: Automotive industries benefit from ISCAR’s carbide inserts for turning crankshafts and camshafts efficiently due to their high-speed capabilities.

- General Metalworking: For general metalworking applications like stainless steel components, ISCAR’s carbide inserts offer consistent performance and longevity.

Advanced Applications

Extra Long Solid Carbide Drills

In the realm of metalworking precision, ISCAR introduces a groundbreaking innovation with their new line of extra long solid carbide drills. These drills, available in lengths of 30xD, 40xD, and 50xD, cater to a wide array of applications demanding extended reach and accuracy. The applications of these extra-long drills span across diverse industries and materials:

- Aerospace Engineering: ISCAR’s extra long solid carbide drills are ideal for aerospace components requiring deep-hole drilling with utmost precision. The drills ensure clean cuts and dimensional accuracy even in challenging aerospace alloys.

- Oil & Gas Sector: In the oil and gas sector, these drills excel in drilling through hardened steel casings with ease and efficiency. Their extended length allows for reaching depths that traditional drills cannot access.

- Automotive Manufacturing: Automotive manufacturers benefit from the versatility of ISCAR’s extra long solid carbide drills when creating intricate parts like engine blocks and transmission components. The drills offer high-performance drilling capabilities for various automotive materials.

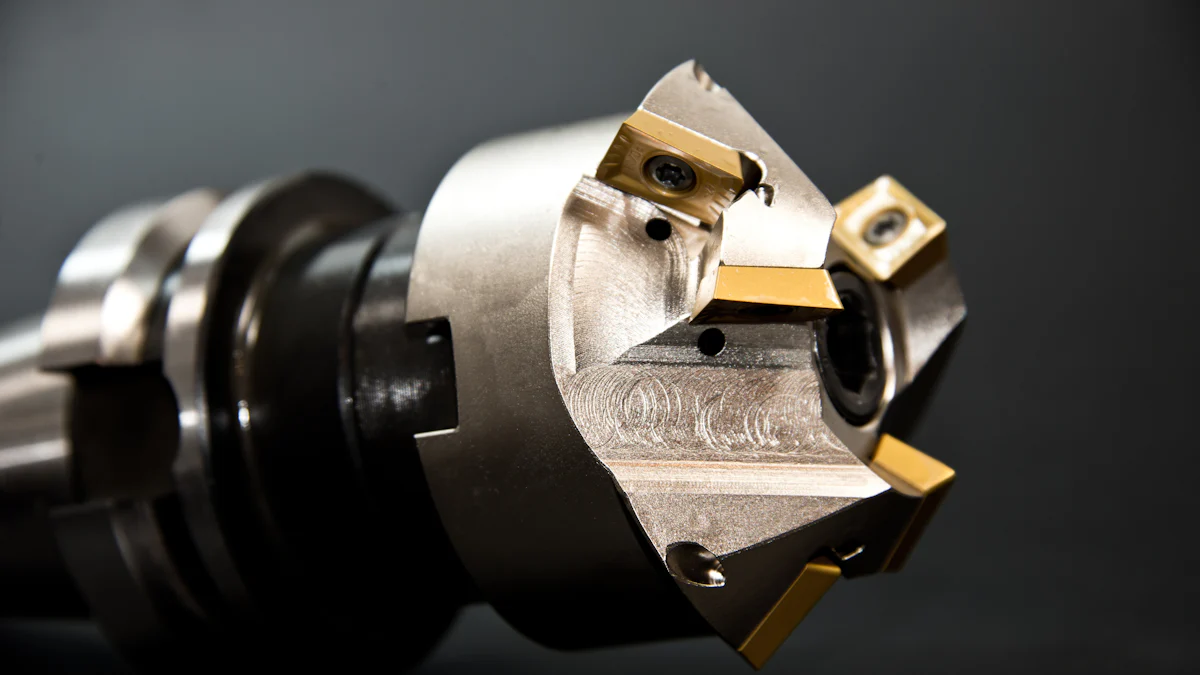

MULTI-MASTER Milling Heads

ISCAR’s MULTI-MASTER milling heads represent a pinnacle of versatility in metalworking operations. These cutting-edge tools expand the horizons of milling applications by offering a range of benefits:

“The MULTI-MASTER system provides a modular approach to milling operations, allowing for quick tool changes and increased machining flexibility.”

- Modularity: With interchangeable cutting heads, the MULTI-MASTER system enables swift transitions between different milling profiles without the need for extensive tool changes.

- Precision Machining: The precise engineering of these milling heads ensures consistent part quality and surface finish across various materials, enhancing overall machining accuracy.

- Cost Efficiency: By reducing setup times and tool changeovers, the MULTI-MASTER system optimizes production processes, leading to cost savings and improved operational efficiency.

Ceramic Grades in Aerospace

ISCAR’s commitment to innovation shines through with their latest ceramic grades, IS35 and IS25, tailored for aerospace applications. These ceramic inserts redefine performance standards in aerospace machining by offering:

- Heat Resistance: ISCAR’s ceramic grades exhibit exceptional resistance to high temperatures encountered during aerospace material processing, ensuring tool longevity under extreme conditions.

- Material Compatibility: Designed specifically for aerospace alloys like titanium and nickel-based superalloys, IS35 and IS25 deliver superior cutting performance while maintaining dimensional integrity.

- Surface Finish Quality: The use of ceramic grades results in impeccable surface finishes on aerospace components, meeting stringent industry requirements for precision and aesthetics.

In conclusion, ISCAR cutting tools epitomize precision and innovation in the metalworking sphere. The blog has showcased the diverse range of cutting tools offered by ISCAR, from carbide inserts to extra long solid carbide drills. Metalworkers benefit immensely from ISCAR’s commitment to technological advancements and tailored solutions. Exploring ISCAR’s product line opens doors to enhanced efficiency and quality in metalworking processes. Embrace excellence with ISCAR’s cutting tools for unparalleled craftsmanship.