A triangle screwdriver bit offers a unique design that fits perfectly into triangular screw heads. This tool ensures precision and efficiency in various applications. The rugged magnetic design increases tightening efficiency, making it ideal for high-intensity tasks like electronics and automotive repair. Using the correct tool for specific jobs prevents damage and ensures safety. Selecting the right size and material, like heat-treated S2 steel, enhances durability and performance. You’ll find that choosing the right screwdriver bit makes your work smoother and more effective.

Understanding Triangle Screwdriver Bits

What is a Triangle Screwdriver Bit?

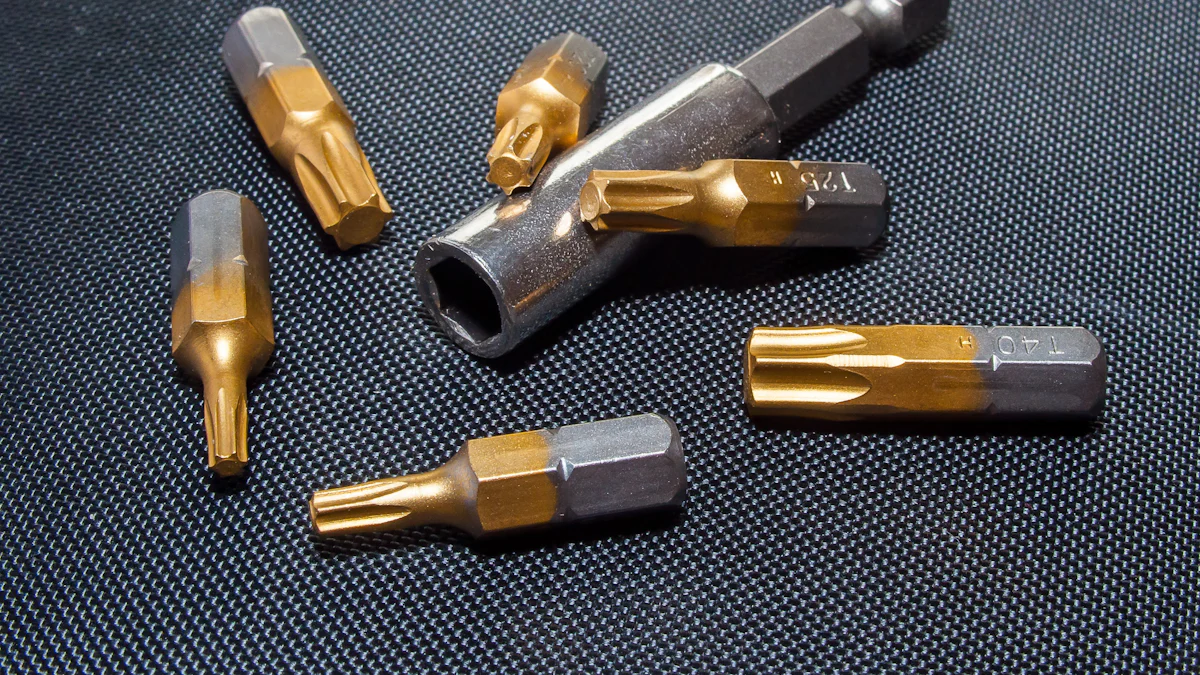

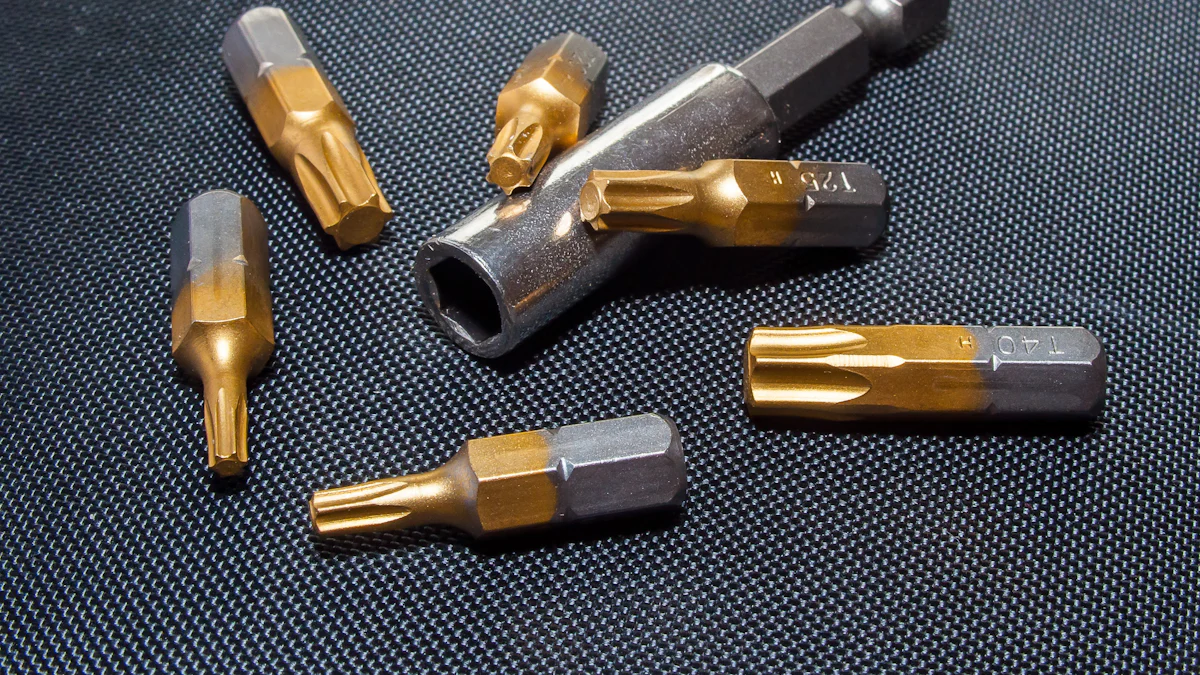

A triangle screwdriver bit has a unique design that fits triangular screw heads. This tool stands out because of its specific shape and functionality. The triangle shape allows for a secure grip on screws that have triangular recesses. This design ensures that the bit does not slip during use. Many industries rely on this tool for its precision and reliability.

Design and Features

The design of a triangle screwdriver bit includes three sides that form a perfect triangle. Each side fits snugly into the triangular recess of a screw head. This feature prevents any wobbling or slipping. The bit often comes in various sizes to match different screw dimensions. A magnetic tip may also be present, which helps hold the screw in place. This feature makes tasks easier and more efficient.

Common Uses and Applications

Triangle screwdriver bits find use in several fields. Electronics repair technicians often use these bits to open devices with security screws. The automotive industry also benefits from these tools for specialized components. Home appliances sometimes feature triangular screws for added security. The versatility of these bits makes them valuable in many applications.

Importance of Selecting the Correct Size

Choosing the right size for a triangle screwdriver bit is crucial. An incorrect size can lead to problems during use. The right size ensures that the bit fits perfectly into the screw head. This fit prevents damage and ensures smooth operation.

Preventing Damage to Screw Heads

Using the correct size helps prevent damage to screw heads. A bit that is too large or small can strip the screw. Stripped screws become difficult to remove and may require additional tools. Proper sizing maintains the integrity of the screw head. This practice saves time and effort in the long run.

Ensuring Proper Fit and Function

A proper fit ensures that the screwdriver bit functions as intended. The right size allows for maximum torque without slipping. This fit provides a secure grip on the screw, making tasks more efficient. The correct size also extends the life of both the bit and the screw. Consistent performance becomes achievable with the right fit.

Step-by-Step Guide to Using a Triangle Screwdriver Bit

Preparing for Use

Gathering Necessary Tools

Start by gathering all the necessary tools. A triangle screwdriver bit is essential for this task. Make sure you have the correct size of the bit. A magnetic screwdriver handle can also be helpful. This handle will make it easier to hold the screws in place. Keep a small container nearby. Use it to store screws safely while working.

Ensuring Safety Precautions

Safety should always come first. Wear safety goggles to protect your eyes. Loose clothing can get caught, so wear fitted clothes. Ensure your workspace is well-lit. A bright light helps you see the screw heads clearly. Keep your work area clean and organized. A clutter-free space reduces the risk of accidents.

Using the Triangle Screwdriver Bit

‘Righty Tighty, Lefty Loosey’ Rule

Remember the ‘Righty Tighty, Lefty Loosey’ rule. Turn the triangle screwdriver bit clockwise to tighten screws. Turn it counterclockwise to loosen them. This rule applies to most screws. Always check the direction before applying force. This step prevents damage to the screw head.

Applying Proper Pressure and Angle

Apply the right amount of pressure when using the triangle screwdriver bit. Too much pressure can strip the screw. Not enough pressure can cause slipping. Hold the screwdriver at a straight angle. An angled approach can damage the screw head. Keep your wrist steady while turning the screwdriver. A firm grip ensures better control and precision.

Common Applications and Industries

Triangle screwdriver bits find their place in various industries. These bits offer unique advantages that enhance both performance and efficiency. Let’s dive into some common applications where these tools shine.

Electronics Industry

The electronics industry relies heavily on triangle screwdriver bits. These bits handle delicate components with precision. The unique design ensures a secure fit in triangular screw heads. This feature prevents slipping and potential damage to sensitive devices.

Devices and Components

In electronics, many devices use security screws. Triangle screwdriver bits fit perfectly into these screws. This fit allows technicians to open and close devices without hassle. Whether working on smartphones or laptops, these bits provide reliability. The snug fit ensures no wobbling during use. This stability is crucial for maintaining device integrity.

Maintenance and Repair

Maintenance tasks in electronics often require precision. Triangle screwdriver bits offer the accuracy needed for such tasks. These bits help in disassembling and reassembling electronic components. The magnetic tip holds screws securely, preventing loss. This feature speeds up the repair process. Using the right bit size prevents stripping, ensuring long-term device health.

Aerospace Industry

The aerospace industry demands high standards of safety and precision. Triangle screwdriver bits meet these standards with ease. The durability of these bits makes them ideal for aerospace applications. The use of S2 steel enhances wear resistance, ensuring long-term use.

Specialized Equipment

Aerospace equipment often features specialized screws. Triangle screwdriver bits fit these screws perfectly. The bits provide a secure grip, essential for high-intensity conditions. This grip ensures that screws remain tight during operation. The increased tightening efficiency reduces maintenance time.

Safety and Precision

Safety is paramount in aerospace applications. Triangle screwdriver bits contribute to this by ensuring precise screw handling. The bits prevent over-tightening, which can lead to component failure. The precision offered by these tools enhances overall safety. Technicians rely on these bits for their reliability and effectiveness.

Troubleshooting and Alternative Solutions

Using a triangle screwdriver bit can sometimes lead to challenges. You might encounter issues like stripped screws or tight screws that refuse to budge. Don’t worry, though. You can troubleshoot these problems and find alternative solutions.

Troubleshooting Common Issues

Stripped Screws

Stripped screws can be a real headache. The triangle screwdriver bit might slip, making it hard to turn the screw. To fix this, try using a rubber band. Place the rubber band over the screw head. Press the triangle screwdriver bit into the rubber band. This method gives extra grip. You can also use pliers to grip the screw head if it’s exposed enough. Patience is key when dealing with stripped screws.

Stuck or Tight Screws

Stuck screws can test your patience. Apply a little penetrating oil to the screw. Let it sit for a few minutes. The oil helps loosen the screw. Use the triangle screwdriver bit to try again. If the screw remains stubborn, gently tap the screwdriver handle with a hammer. This action can help break the seal. Persistence often pays off with tight screws.

Alternative Methods

Sometimes, you might not have a triangle screwdriver bit on hand. In such cases, alternative methods can save the day.

Using a Flat Screwdriver

A flat screwdriver can work in a pinch. Choose a flathead that fits snugly into the triangular recess. Apply steady pressure while turning. This method might not be perfect, but it can get the job done. Many people have found success with this approach. Adaptability is a valuable skill when working with tools.

Using a Hex Wrench

A hex wrench offers another alternative. Find a hex wrench that fits tightly into the triangle screw head. Turn the wrench carefully. This method requires patience and precision. A hex wrench can serve as a temporary substitute for a triangle screwdriver bit. Resourcefulness can solve many problems in tool use.

Using the right tool makes all the difference. A triangle screwdriver bit ensures precision and efficiency in your projects. You can avoid damage and enhance performance by selecting the correct size. The versatility of a triangle screwdriver bit shines in various industries, from electronics to aerospace. Many users find satisfaction when the triangle screwdriver bit fits perfectly, like a dream. So, apply this knowledge and experience the benefits firsthand. Embrace the utility of a triangle screwdriver bit and tackle your tasks with confidence.