A small torque wrench is a precision tool designed to apply a specific torque to fasteners such as bolts and nuts. Proper usage ensures that fasteners achieve the correct tension, preventing damage and ensuring safety. Using a torque wrench correctly is crucial in various applications, including automotive repair, bike maintenance, and mechanical projects. Incorrect torque can lead to equipment failure or safety hazards. Understanding how to use a small torque wrench effectively can enhance the longevity and reliability of mechanical assemblies.

Understanding the Basics of a Small Torque Wrench

What is a Small Torque Wrench?

Definition and Purpose

A small torque wrench is a precision tool designed to apply a specific amount of torque to fasteners like bolts and nuts. This tool ensures that fasteners achieve the correct tension, which prevents damage and promotes safety. The primary purpose of a small torque wrench is to provide accurate torque application in various mechanical tasks.

Types of Torque Wrenches

Several types of torque wrenches exist, each suited for different applications. The most common types include:

- Click-Type Torque Wrench: Produces an audible click when the desired torque is reached.

- Beam Torque Wrench: Uses a scale and pointer to indicate the applied torque.

- Dial Torque Wrench: Features a dial gauge to show the torque value.

- Electronic Torque Wrench: Provides digital readings for precise torque measurement.

Each type offers unique advantages depending on the specific requirements of the task.

Why Use a Small Torque Wrench?

Importance of Accurate Torque

Accurate torque application is crucial for the integrity of mechanical assemblies. Properly tightening fasteners ensures that components remain secure and function as intended. Expert testimony highlights that “understanding proper use of a torque wrench is important in order to obtain the clamping loads needed for any given application.” Accurate torque prevents over-tightening or under-tightening, which can lead to equipment failure.

Consequences of Incorrect Torque

Incorrect torque application can have serious consequences. Over-tightening can strip threads, damage components, or cause fasteners to break. Under-tightening can result in loose fasteners, leading to mechanical failure or safety hazards. Ensuring the correct torque with a small torque wrench enhances the longevity and reliability of mechanical assemblies.

Step-by-Step Guide to Using a Small Torque Wrench

Preparation

Selecting the Right Torque Wrench

Choosing the correct small torque wrench is essential for achieving accurate results. Consider the torque range required for the task. Ensure the selected wrench can handle the specific torque values needed. For example, automotive repairs often demand different torque ranges compared to bike maintenance. Always verify the torque specifications provided by the manufacturer of the equipment being worked on.

Calibrating the Torque Wrench

Calibration ensures that a small torque wrench provides precise measurements. Follow the manufacturer’s instructions for calibration. Use a calibration device if available. Regular calibration maintains the accuracy of the tool. Before each use, inspect the wrench for any signs of wear or damage. A well-calibrated wrench enhances the reliability of mechanical assemblies.

Using the Small Torque Wrench

Setting the Desired Torque

Set the desired torque value on the small torque wrench before starting the task. Most wrenches have a scale or digital display for setting the torque. Turn the handle to adjust the torque value. Ensure the locking mechanism is engaged to prevent accidental changes. Accurate settings are crucial for achieving the correct tension in fasteners.

Applying the Torque

Hold the body of the small torque wrench with one hand to stabilize it. Use the other hand to turn the handle clockwise. Apply steady pressure until the wrench clicks or indicates the desired torque has been reached. The click sound and feel provide an audible and tactile indication of reaching the set torque. Avoid using excessive force to prevent over-tightening.

Checking the Torque

After applying the torque, double-check the fastener to ensure it has achieved the correct tension. Use the small torque wrench to verify the applied torque. If necessary, make slight adjustments. Consistent verification ensures that all fasteners meet the specified torque requirements. Properly tightened fasteners enhance the safety and longevity of mechanical assemblies.

Tips for Effective Use of a Small Torque Wrench

Best Practices

Consistent Technique

Maintain a consistent technique when using a small torque wrench. Hold the body of the wrench with one hand to stabilize it. Use the other hand to turn the handle. Apply steady pressure until the desired torque is reached. Consistency ensures accurate torque application every time.

Avoiding Common Mistakes

Avoid common mistakes to ensure proper use of a small torque wrench. Do not use the wrench to loosen fasteners. Always set the correct torque value before starting. Verify the torque setting after each use. Prevent over-tightening by stopping at the click or indication. Regularly inspect the wrench for wear and damage.

Maintenance and Care

Cleaning the Torque Wrench

Regular cleaning maintains the accuracy of a small torque wrench. Use a soft cloth to wipe down the wrench after each use. Remove any dirt or debris from the tool. Avoid using harsh chemicals that can damage the wrench. Proper cleaning extends the life of the tool.

Storing the Torque Wrench

Store the small torque wrench in a dry place. Use the case provided by the manufacturer. Keep the wrench away from moisture to prevent rust. Store the wrench at its lowest torque setting to maintain calibration. Proper storage ensures the longevity of the tool.

Regular Calibration

Regular calibration ensures the accuracy of a small torque wrench. Follow the manufacturer’s instructions for calibration. Use a calibration device if available. Calibrate the wrench at least once a year. Regular calibration maintains the reliability of the tool.

Advanced Information on Small Torque Wrenches

Specialized Applications

Automotive Use

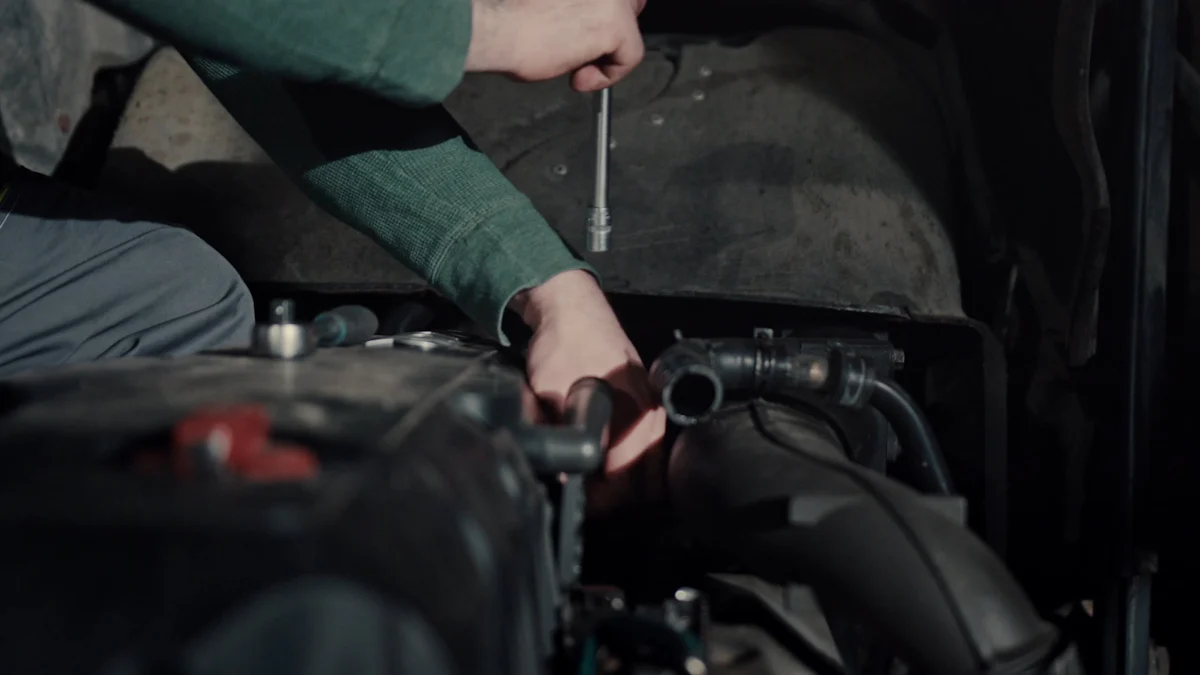

Small torque wrenches play a crucial role in automotive applications. Mechanics use these tools to ensure that bolts and nuts achieve the correct tension. Proper torque application prevents damage to vehicle components and enhances safety. For example, tightening lug nuts on wheels requires precise torque to avoid wheel detachment or brake rotor warping. Using a small torque wrench in automotive repair ensures that all fasteners meet manufacturer specifications.

Industrial Use

In industrial settings, small torque wrenches are indispensable for maintaining machinery and equipment. Accurate torque application ensures that mechanical assemblies operate efficiently and safely. Industries such as aerospace, manufacturing, and construction rely on these tools for critical tasks. For instance, assembling machinery parts with the correct torque prevents operational failures and extends equipment lifespan. Small torque wrenches help maintain the integrity of industrial systems by providing precise torque control.

Troubleshooting

Identifying Issues

Identifying issues with a small torque wrench involves regular inspection and testing. Users should check for signs of wear, damage, or calibration drift. A torque wrench that produces inconsistent results may indicate a problem. For example, if the wrench fails to click at the set torque, it may require recalibration. Regularly testing the wrench against a known standard helps identify accuracy issues. Ensuring the tool remains within tolerance levels is essential for reliable performance.

Solutions and Fixes

Solutions for common torque wrench issues include recalibration, cleaning, and part replacement. Recalibration restores the tool’s accuracy and should occur at least once a year. Cleaning the wrench after each use removes debris that can affect performance. Replacing worn or damaged parts ensures the tool functions correctly. Following the manufacturer’s maintenance guidelines helps keep the torque wrench in optimal condition. Addressing issues promptly maintains the reliability and longevity of the tool.

Using a small torque wrench effectively ensures the safety and reliability of mechanical assemblies. Following the provided steps and tips guarantees accurate torque application, preventing damage and enhancing performance. Regular maintenance and proper storage extend the tool’s lifespan. Investing in a high-quality torque wrench saves money by avoiding inefficiencies and frequent replacements. Routine calibration preserves accuracy, making the tool indispensable for critical applications. Proper handling and care maintain the precision of the torque wrench, ensuring optimal results in every task.

See Also

Scooter Upgrades: High-Quality Parts for Peak Performance

Discovering Diverse Sock Styles for Both Genders

Mastering Winter Comfort with Soft Towel Sock Essentials