Selecting the right circle cutting tool holds immense importance for achieving precise and accurate cuts. Precision tools have gained significant traction, with the market projected to reach US$ 102 billion by 2027, growing at a CAGR of 13.6%. Circle cutting tools cater to various materials like sheet metal, brass, copper, soft steel, aluminum, plastic, wood, and composition materials. Key factors to consider include material compatibility, precision, ease of use, safety features, and durability. Versatile tools offer adjustability for different sizes, ensuring flexibility and efficiency in various applications.

Types of Circle Cutting Tools

Manual Circle Cutters

Manual circle cutters offer simplicity and control. Users can operate these tools without electricity. Fiskars® Circle Cutter stands out for its design and ease of use. This tool allows users to create precise circles, making it ideal for crafting.

Features and Benefits

Manual circle cutters provide several benefits:

- Portability: Users can carry these tools anywhere.

- Control: Users can adjust the cutting pressure manually.

- Affordability: These tools often cost less than electric or CNC options.

Best Use Cases

Manual circle cutters work best for:

- Crafting: Scrapbooking and other paper crafts.

- Small Projects: Tasks that do not require high volume cuts.

- Versatile Materials: Cutting paper, vinyl, and thin plastics.

Electric Circle Cutters

Electric circle cutters offer speed and efficiency. These tools use power to cut through materials quickly. Circle Cutter: Adjustable for Wood, Metal Cutting Tool exemplifies this category. The tool provides adjustable diameters, making it versatile for various projects.

Features and Benefits

Electric circle cutters come with notable features:

- Speed: Faster cutting compared to manual tools.

- Consistency: Uniform cuts with minimal effort.

- Adjustability: Options to change cutting diameters easily.

Best Use Cases

Electric circle cutters excel in:

- Woodworking: Cutting circles in wood and metal.

- High Volume Projects: Tasks requiring multiple cuts.

- Precision Work: Jobs needing consistent and accurate results.

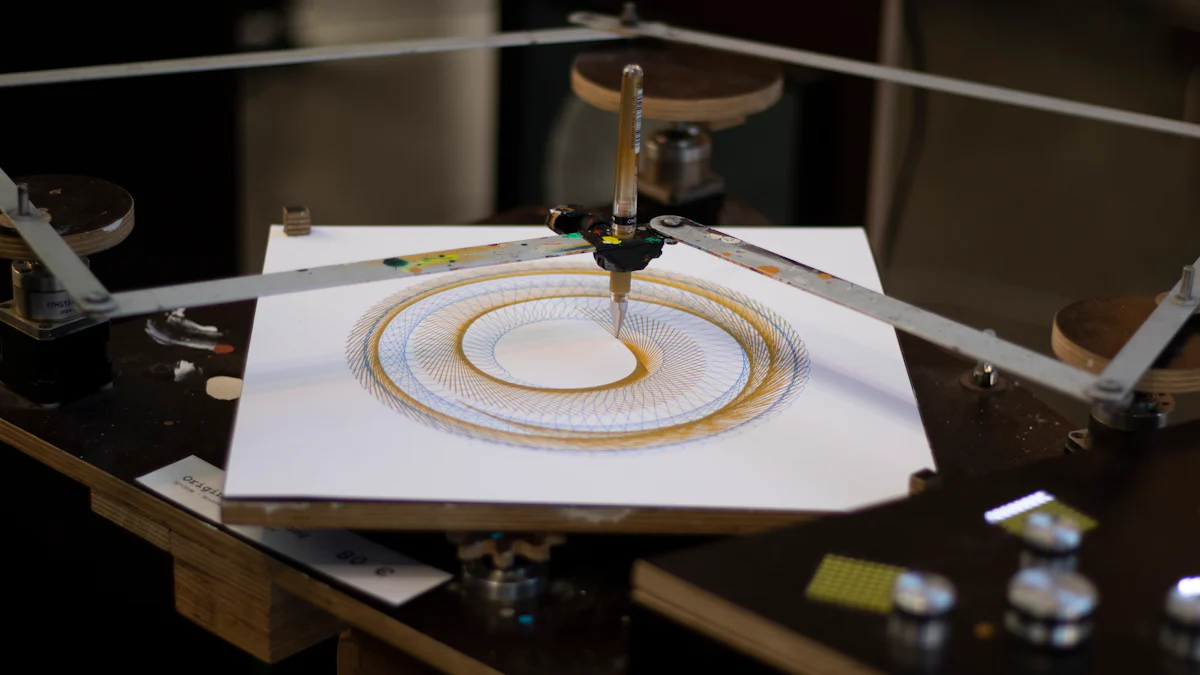

CNC Circle Cutting Machines

CNC circle cutting machines represent the pinnacle of precision and automation. These machines use computer numerical control to achieve exact cuts. KW-triO Crafting Circular Adjustable Diameter offers an efficient angle scale for precise cutting.

Features and Benefits

CNC circle cutting machines provide advanced features:

- Precision: High accuracy in every cut.

- Automation: Minimal manual intervention required.

- Durability: Built to handle heavy-duty tasks.

Best Use Cases

CNC circle cutting machines are ideal for:

- Industrial Applications: Large-scale manufacturing.

- Complex Designs: Intricate patterns and shapes.

- Material Versatility: Cutting a wide range of materials, including metals and plastics.

Key Factors to Consider

Material Type

Compatibility with Different Materials

Circle cutting tools must handle various materials effectively. Tools like the Dremel Circle Cutter Attachment offer precise cuts in materials such as wood, metal, and plastic. Compatibility ensures that the tool can perform well across different projects. The THINNERLINE Circle Cutter excels in cutting thin materials up to 0.2mm, making it ideal for aircraft and military modeling.

Durability and Longevity

Durable circle cutting tools provide long-term value. High-quality materials like stainless steel or robust plastics enhance the lifespan of the tool. For instance, the Fiskars® Circle Cutter combines user-friendly design with durable construction. Investing in a durable tool reduces the need for frequent replacements, saving money over time.

Precision and Accuracy

Tolerance Levels

Precision remains crucial for achieving accurate results. Tools like the Adjustable Circle Cutters offer smooth and precise cuts. High tolerance levels ensure that the tool can produce consistent results. This feature becomes essential for tasks requiring exact measurements and intricate designs.

Ease of Adjustment

Ease of adjustment enhances the user experience. Adjustable circle cutters allow users to change the diameter effortlessly. The KW-triO Crafting Circular Adjustable Diameter tool exemplifies this feature. Quick adjustments save time and improve efficiency, especially in high-volume projects.

Speed and Efficiency

Cutting Speed

Cutting speed impacts overall productivity. Electric circle cutters, such as the Circle Cutter: Adjustable for Wood, Metal Cutting Tool, provide faster cutting compared to manual options. Increased speed allows users to complete tasks more quickly, making these tools suitable for large-scale projects.

Time-Saving Features

Time-saving features add value to circle cutting tools. Automation in CNC machines minimizes manual intervention. The KW-triO Crafting Circular Adjustable Diameter tool offers an efficient angle scale for precise cutting. These features streamline the cutting process, enhancing overall efficiency.

Comparing Different Circle Cutting Tools

Advantages and Disadvantages

Manual vs. Electric

Manual circle cutting tools offer simplicity and control. Users can operate these tools without electricity. Portability remains a significant advantage. Manual tools often cost less than electric options. However, manual tools require more effort and time. Precision may vary based on user skill.

Electric circle cutting tools provide speed and efficiency. These tools use power to cut through materials quickly. Consistency in cuts becomes easier to achieve. Adjustability allows users to change cutting diameters effortlessly. However, electric tools often come with higher costs. Dependence on electricity can limit portability.

Electric vs. CNC

Electric circle cutting tools excel in speed and ease of use. Users can complete high-volume projects quickly. Adjustability enhances versatility for different sizes. However, electric tools may lack the precision of CNC machines.

CNC circle cutting machines represent the pinnacle of precision. Automation ensures exact cuts with minimal manual intervention. Durability allows these machines to handle heavy-duty tasks. However, CNC machines come with a high initial investment. Complexity in operation may require specialized training.

Cost Analysis

Initial Investment

Manual circle cutting tools generally have the lowest initial cost. Users can find affordable options suitable for small projects. Electric circle cutting tools require a higher initial investment. Features like adjustability and speed justify the cost. CNC circle cutting machines demand the highest initial investment. Advanced technology and precision capabilities contribute to the cost.

Long-Term Costs

Manual circle cutting tools incur minimal long-term costs. Occasional blade replacements and maintenance suffice. Electric circle cutting tools may involve higher long-term costs. Electricity usage and potential repairs add to expenses. CNC circle cutting machines have significant long-term costs. Maintenance, software updates, and potential repairs increase expenses. However, the precision and efficiency of CNC machines can offset these costs over time.

Tips for Using Circle Cutting Tools

Safety Precautions

Proper Handling

Proper handling of circle cutting tools ensures user safety and tool longevity. Users should always read the manufacturer’s instructions before using any tool. Firmly secure the material to prevent slipping during cutting. Maintain a steady hand and apply consistent pressure. Avoid rushing the process to ensure precise cuts and reduce the risk of accidents.

Protective Gear

Using protective gear is essential when operating circle cutting tools. Safety goggles protect eyes from debris. Gloves offer protection against sharp edges and enhance grip. Ear protection may be necessary for electric and CNC circle cutting machines due to noise levels. Wearing appropriate footwear prevents foot injuries from falling objects.

Maintenance and Care

Regular Cleaning

Regular cleaning of circle cutting tools maintains their efficiency and extends their lifespan. After each use, remove any debris or residue from the tool. Use a soft brush or cloth to clean the blades and other components. For electric and CNC machines, follow the manufacturer’s guidelines for cleaning electrical parts. Proper cleaning prevents buildup that can affect cutting precision.

Sharpening and Replacing Blades

Sharpening and replacing blades are crucial for maintaining the performance of circle cutting tools. Dull blades can lead to inaccurate cuts and increased effort. Use a sharpening stone or a dedicated blade sharpener to keep blades in optimal condition. Replace blades when sharpening no longer restores their edge. Regular maintenance ensures that the tools deliver precise and efficient results.

Selecting the perfect circle cutting tool requires careful consideration of several factors. Precision and accuracy ensure consistent results across various materials. Versatility allows the tool to handle diverse projects, maximizing its utility. Ease of use, including adjustable settings and ergonomic designs, enhances the user experience. Safety precautions protect users and maintain a secure working environment. Durability and longevity provide long-term value. Each user should evaluate individual needs and preferences to make an informed decision. Choosing the right tool ensures efficiency and satisfaction in any cutting task.