When faced with the frustration of stripped screws, the work material and your day are at risk of being ruined. As extractors become essential tools in such situations, their significance cannot be overlooked. This blog aims to delve into the world of screwdriver extractors, exploring their role in solving common problems and enhancing efficiency. By understanding the importance of these tools, readers will gain valuable insights into maintaining smooth operations in various applications.

The Importance of Screwdriver Extractors

When faced with stripped screws, the need for screwdriver extractors becomes evident. These tools play a crucial role in various applications by providing solutions to common problems and enhancing operational efficiency.

Solving Common Problems

Dealing with stripped screws can be a daunting task without the right tools. Screw extraction sets offer instruments designed for minimally invasive screw removal, ensuring that even in difficult situations, screws can be extracted efficiently. This enables users to tackle stripped screws effectively, preventing delays and material damage.

Time-saving benefits are another advantage of utilizing screwdriver extractors. With tools like spiral flute screw extractors, which feature curved flutes for deeper extraction, users can rely on their ability to remove most fasteners quickly and reliably. This saves valuable time and effort, making operations more efficient overall.

Enhancing Efficiency

Precision is paramount when working with small parts, emphasizing the need for tools like screwdriver extractors that provide accuracy. By using these tools correctly, such as those included in a comprehensive screw extraction set, users can ensure precision in their work on intricate components. This precision ultimately leads to better results and prevents damage to delicate parts.

Versatility is another key aspect of screwdriver extractors that enhances operational efficiency. Tools like spiral flute screw extractors offer flexibility in handling various types of fasteners, making them suitable for a wide range of applications. This versatility allows users to address different challenges effectively, ensuring smooth operations across different projects.

Types of Screwdriver Extractors

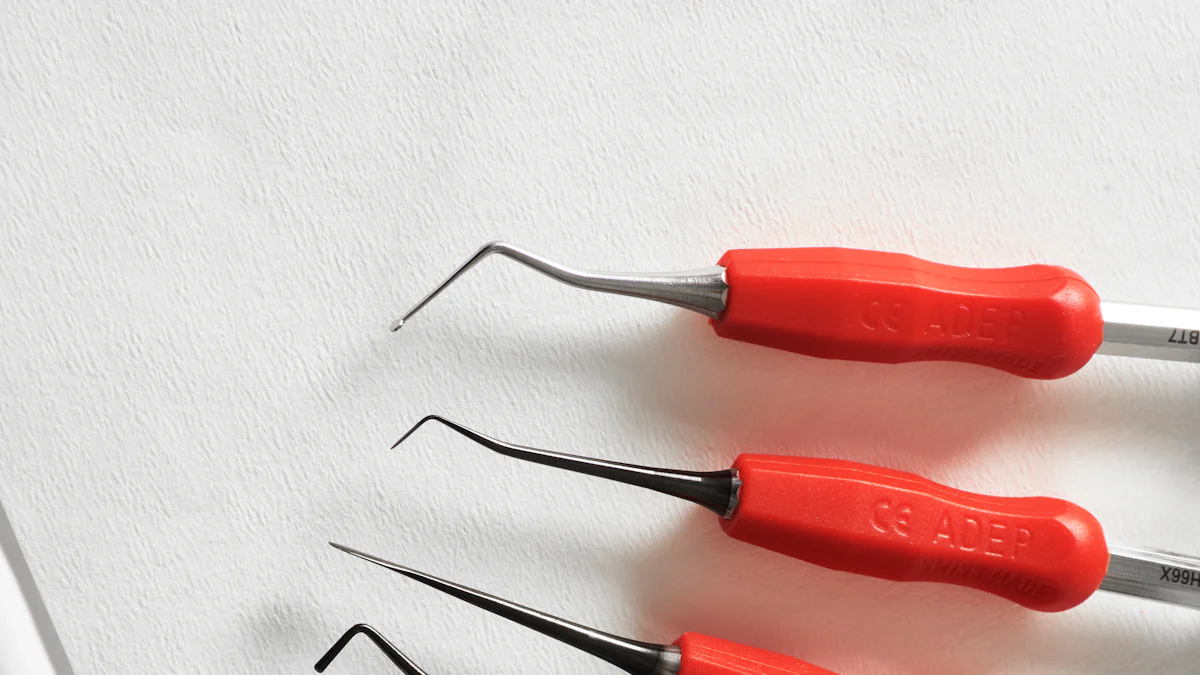

When it comes to screwdriver extractors, understanding the different types available can significantly impact the efficiency of your maintenance tasks. From basic screw extractors to precision screw extractors, each type serves a specific purpose in handling various screws effectively.

Basic Screw Extractors

Features and Uses:

- Hex-Out Damaged Socket Screw Extractors: These specialized tools are designed to remove stripped socket head screws without the need for drilling. They provide a solution for challenging situations where traditional methods may not work efficiently.

- Screw Extraction Set: This comprehensive set includes a variety of instruments tailored for minimally invasive screw removal. The Slim Screw Extraction Forceps, included in the set, enable users to remove screws with or without rotating the screwdriver, offering versatility in extraction methods.

Common Brands:

- ExtractorPro: Known for its durable and reliable basic screw extractors that cater to a wide range of screw sizes and materials.

- SwiftExtract: Offers innovative solutions in basic screw extraction, focusing on ease of use and efficiency in removing damaged screws.

Precision Screw Extractors

Applications in Small Parts:

Precision screw extractors play a crucial role when working with intricate components such as watches or delicate machinery parts. Their x-shape tip design ensures efficient extraction without causing further damage to small parts.

Advantages Over Basic Extractors:

- Sharp Reverse-Screw Pattern: Unlike some ineffective precision screw extractors with x-shape tips, actual working precision extractors feature a sharp reverse-screw pattern that cuts into metal when rotated counter-clockwise, providing optimal extraction results.

By understanding the distinctions between basic and precision screw extractors, users can choose the right tool for their specific maintenance needs, ensuring smooth operations and efficient screw removal processes.

Maintenance Tips for Screwdriver Extractors

Regular Inspection

Inspecting screwdriver extractors regularly is essential to ensure their optimal performance and longevity. By checking for wear and tear, users can identify any signs of damage and take necessary actions to maintain the tools in top condition.

- Look for Signs of Wear: Examine the extractor blades for any signs of wear, such as dull edges or deformities. This inspection helps prevent potential issues during operation and ensures efficient screw removal.

- Monitor Tool Integrity: Regularly assess the overall integrity of the extractors, including handles and grips. Any loose components or structural weaknesses should be addressed promptly to avoid accidents and maintain user safety.

Proper Usage

Using screwdriver extractors correctly is crucial for successful screw extraction and preventing damage to both the tool and the fastener. By following proper usage guidelines, users can maximize the effectiveness of their tools while avoiding common mistakes that may compromise extraction results.

- Select the Right Size: Ensure that you choose an extractor size that matches the screw dimensions accurately. Using an incorrect size can lead to slippage, damaging the screw head further. Refer to manufacturer guidelines or sizing charts for proper selection.

- Avoid Common Mistakes: When using screwdriver extractors, avoid excessive force or improper alignment with the screw head. Applying too much pressure can break the extractor or cause it to slip, resulting in a more challenging extraction process.

By incorporating these maintenance tips into your routine, you can prolong the lifespan of your screwdriver extractors and ensure smooth operations during screw removal tasks.

Screwdriver extractors play a vital role in maintaining operational efficiency by swiftly addressing stripped screws and broken fasteners. The diverse types, from basic to precision extractors, offer tailored solutions for various maintenance needs. Regular inspection and proper usage are key in ensuring the longevity of these tools. Moving forward, incorporating these maintenance tips will guarantee smooth operations and prevent delays caused by damaged screws. Remember, a well-maintained extractor is the cornerstone of successful repair and maintenance tasks.

Testimonials:

Unknown

It’s probably happened to you at some point, whether you’re a DIYer or you work in repair and maintenance. You stripped or broke a screw or bolt, and it refuses to budge. Broken fasteners are not just frustrating; they can ruin your work material and your day if you don’t have a good extractor to remove them.

Unknown

The Slim Screw Extraction Forceps enable the removal of a screw with or without rotation of the screwdriver. The screw is grasped behind the screw head. The forceps arms are slim and stable. They are bent in a way that the closed forceps arms lay parallel and tight to the screwdriver shaft.