Welcome to the world of welding, where precision and stability are paramount. As a high school student exploring the art of welding, it’s crucial to understand the significance of reliable tools in this craft. Welding accidents account for a significant portion of occupational mishaps, emphasizing the need for precise equipment. In this blog, I will introduce you to an incredible tool that revolutionizes welding by providing unparalleled stability and control. Let’s dive into the fascinating realm of welding tools and discover their remarkable benefits.

Introduction to Welding Tools

Understanding the Basics

Welding is the process of joining two or more metal pieces by melting and fusing them together. It requires precise control of heat levels to ensure the structural integrity and mechanical properties of the welded joint. Common tools used in welding include welding machines, electrodes, protective gear such as helmets and gloves, clamps, and various hand tools for cutting and shaping metal.

What is Welding?

Welding involves using heat to melt and fuse metal pieces together, creating a strong bond. Controlling heat levels during the welding process is crucial to ensure the entire assembly is strong, durable, and reliable.

Common Tools in Welding

- Welding Machines: These devices generate the heat necessary for melting metals.

- Electrodes: They act as a filler material that melts along with the base metals to form a strong joint.

- Protective Gear: Helmets, gloves, and aprons protect welders from sparks, UV radiation, and molten metal splatter.

- Clamps: These tools hold workpieces in place during welding operations.

- Hand Tools: Cutting torches, grinders, chipping hammers, wire brushes, and measuring tools are essential for preparing and finishing welded joints.

The Role of Stability in Welding

Proper stability is essential for achieving high-quality welds. TIG welding, known for its precision and quality surpassing other forms of welding, requires meticulous control over every variable. Without proper support and stability, achieving consistent results becomes challenging.

Challenges Without Proper Support

Inadequate stability can lead to distortion or misalignment of workpieces during welding. This can compromise the integrity of the weld joint and result in structural weaknesses.

Solutions for Stability

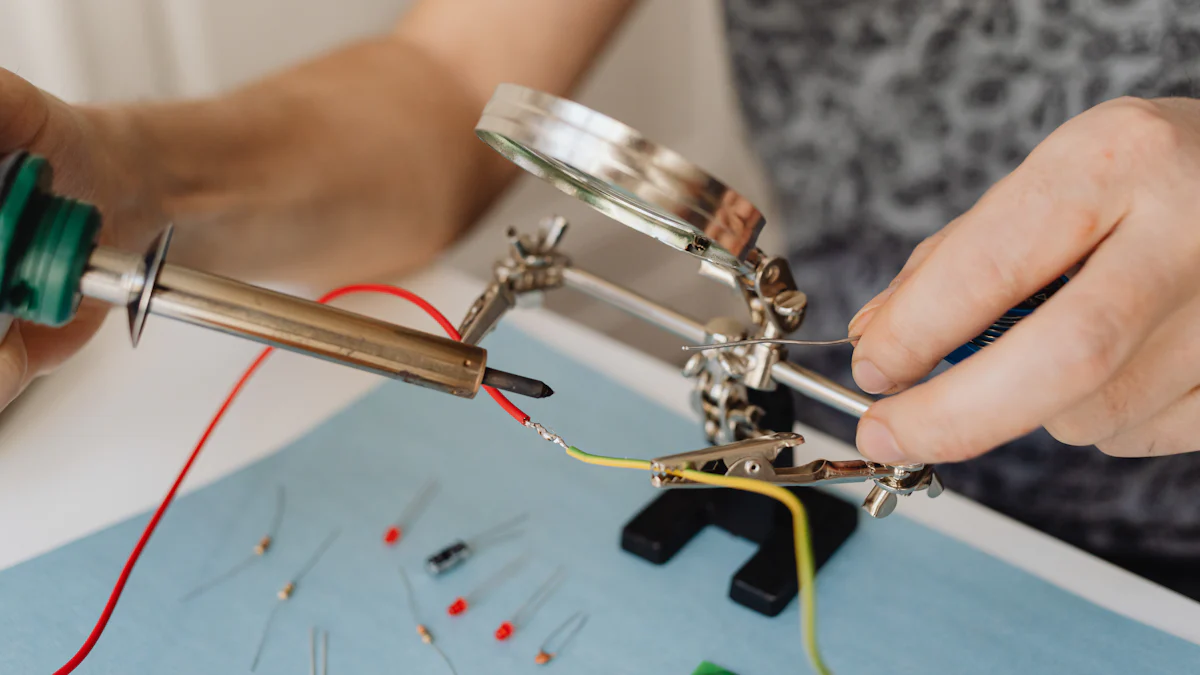

Utilizing specialized tools like the welding third hand tool provides reliable support for workpieces at any angle. This enhances precision by minimizing movement during the welding process. Additionally, it allows welders to access tight or awkward spaces with ease.

By understanding these basics of welding tools and recognizing the importance of stability in welding processes like TIG welding, we can appreciate how innovative solutions like the welding third hand tool significantly enhance efficiency and quality in this craft.

Essential Features of the Welding Third Hand Tool

Now, let’s delve into the essential features that make the welding third hand tool an indispensable asset in the world of welding.

Design and Build

Adjustable Clamps

The welding third hand tool, also known as a welder’s third hand, is designed with adjustable clamps that securely hold the workpiece in place. These clamps can be easily adjusted to accommodate various sizes and shapes of metal pieces, providing stability and precision during the welding process.

Ball Joint Mechanism

One remarkable feature of the welding third hand tool is its innovative ball joint mechanism. This mechanism allows for versatile positioning and locking, ensuring that the workpiece remains steady at any desired angle. The flexibility offered by this ball joint mechanism enables welders to access tight or awkward spaces with ease, enhancing overall efficiency and quality.

Versatility and Adaptability

Positioning for Any Welding Angle

The welding third hand tool offers unparalleled versatility when it comes to positioning workpieces for welding. Whether it’s a horizontal, vertical, or overhead weld, this tool provides the necessary support to position the workpiece at any angle for full weld access. This adaptability simplifies complex welding tasks and ensures consistent results.

Support for Various Materials

Another key benefit of the welding third hand tool is its ability to provide reliable support for various materials. From thin plates to bolts and nuts, this tool can firmly hold stock at the ideal angle and height while welding, cutting, sanding, or painting. Its adaptability makes it an essential companion for welders working with diverse materials and projects.

In addition to these features, products such as Welders 3rd Hand, Third Hand Clamps, Third Hand, and Grasshopper Welding Finger AGH130P offer unique functionalities that cater to specific welding needs. These tools are designed to enhance precision, stability, and control in various welding applications.

Practical Applications and Benefits

Enhancing Welding Precision

The welding third hand tool is a game-changer when it comes to enhancing welding precision. Its ability to firmly hold the workpiece in place at any desired angle allows for full weld access, ensuring that the welding process is not hindered by movement or instability. This firsthand stability experience has been echoed by numerous members of the welding community. For instance, one user shared their personal experience, stating, “Nice build on yours. I use to use vise grips clamped to heavy angle, wasn’t doing enough welding to warrant a homemade one. But seeing yours I will next time I’m welding.” This testimony highlights the practical impact of utilizing a dedicated tool like the welding third hand to achieve precise and stable welds.

Examples from Personal Experience

In my own journey as a welder, I have encountered various scenarios where achieving precision in welding was challenging without adequate support. The introduction of the welding third hand tool transformed these experiences, allowing me to elevate and firmly hold stock at the ideal angle and height while welding, cutting, sanding, or painting. This firsthand experience underscores the significant role this tool plays in enhancing precision and control during welding operations.

Feedback from the Welding Community

Feedback from fellow welders further emphasizes the value of the welding third hand tool in enhancing precision. A member of the community shared their insights: “For the time and effort it takes to make one, a welder’s third hand is probably one of the most useful tools you can have.” Such endorsements from experienced welders highlight how this tool significantly contributes to achieving precise and high-quality welds.

Increasing Efficiency and Safety

Apart from enhancing precision, the welding third hand tool also plays a pivotal role in increasing efficiency and safety during welding processes.

Time-saving Aspects

The versatility offered by this innovative tool translates into significant time-saving benefits for welders. By providing stable support at any angle for various materials, it streamlines complex welding tasks and ensures consistent results with minimal effort. The Original Welders 3rd Hand has been lauded as a one-man pipe welding tool that greatly improves efficiency due to its small, portable nature and adjustable features.

Safety Improvements

Moreover, safety improvements are inherent in using the welding third hand tool. By securely holding workpieces in place during welding operations, it minimizes risks associated with movement or instability. Anecdotal evidence from users further supports this notion; as one user emphasized: “So to avoid that from happening in the future, I added some copper alloy weld metal to all three contact points of the 3rd hand tool.” This proactive approach demonstrates how welders prioritize safety when utilizing tools like the welding third hand, ensuring secure and stable working conditions.

In conclusion, the welding third hand tool offers unparalleled benefits that elevate the precision and safety of welding operations. Its innovative design with adjustable clamps and a ball joint mechanism ensures stability at any angle, enhancing efficiency and quality. As you explore the world of welding tools, consider the impactful role this tool plays in achieving precise welds and streamlining complex tasks. Embracing technology in welding through tools like the welding third hand is a testament to our commitment to excellence in craftsmanship.