Choosing the right spanner wrench is crucial for efficiency and safety in various industries. A proper tool enhances productivity and reduces errors, leading to better quality work. Snap-On, a reputable brand with a rich history, offers high-quality tools trusted by professionals. This blog aims to guide readers in selecting the best Snap-On spanner wrench, ensuring optimal performance and durability.

Understanding Spanner Wrenches

What is a Spanner Wrench?

Definition and Basic Function

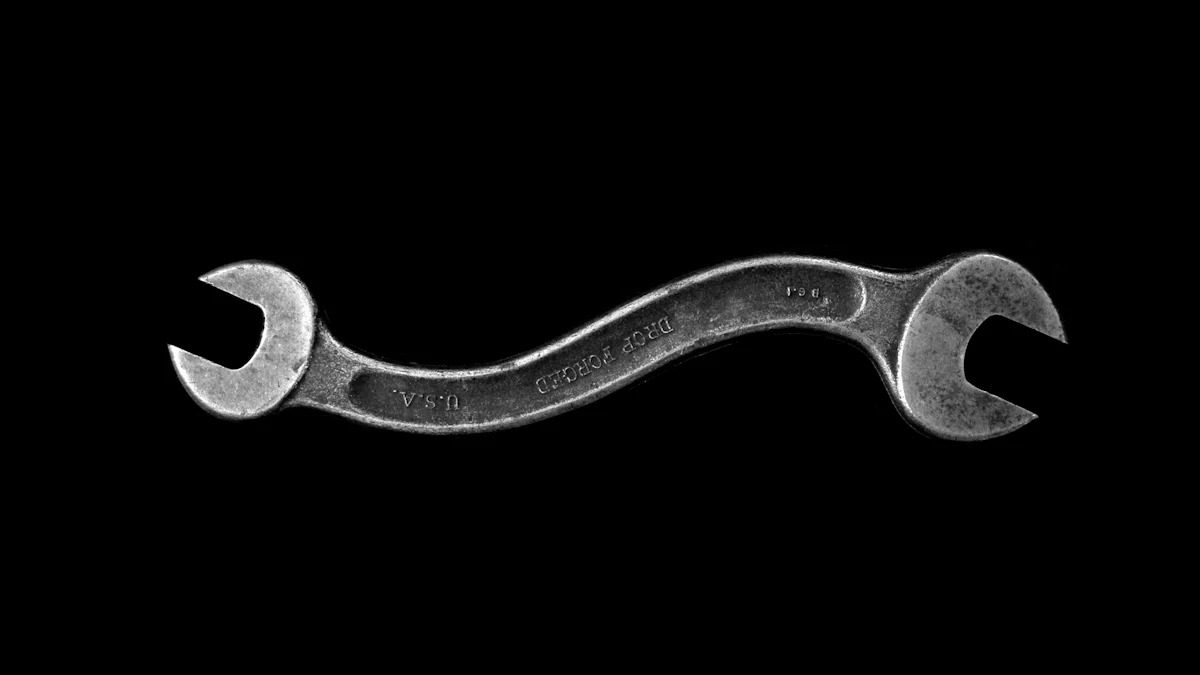

A spanner wrench, also known as a spanner, is a hand tool used to turn fasteners such as nuts and bolts. The tool provides grip and mechanical advantage in applying torque to turn objects. Spanners come in various sizes and shapes to accommodate different fastener types.

Common Uses in Various Industries

Spanner wrenches find applications in numerous industries. Mechanics use them for automotive repairs. Construction workers rely on them for assembling structures. Industrial maintenance teams use spanners for machinery upkeep. Each industry benefits from the versatility and efficiency of these tools.

Types of Spanner Wrenches

Adjustable vs. Fixed

Adjustable spanners feature jaws that can expand or narrow to fit various fastener sizes. This adaptability makes them highly versatile. Fixed spanners, on the other hand, have a set jaw size. These spanners provide a secure fit for specific fasteners. Both types offer unique advantages depending on the task at hand.

Open-end vs. Box-end

Open-end spanners have U-shaped openings at both ends. These spanners allow for quick placement on fasteners. Box-end spanners encircle the fastener head completely. This design provides a more secure grip. Box-end spanners are ideal for high-torque applications.

Combination Wrenches

Combination wrenches offer the best of both worlds. One end features an open-end design, while the other has a box-end. This dual functionality allows users to switch between tasks without changing tools. Combination wrenches enhance efficiency and convenience.

Features of Snap-On Spanner Wrenches

Material and Durability

Types of materials used

Snap-On spanner wrenches use a special alloy steel. This material undergoes precision forging and heat treatment. These processes ensure optimum strength. The alloy steel provides the necessary toughness for demanding tasks.

Longevity and wear resistance

The special alloy steel in Snap-On spanner wrenches offers exceptional longevity. Heat treatment enhances wear resistance. This ensures the tool remains effective over time. The durability of these wrenches reduces the need for frequent replacements. Users can rely on these tools for long-term use.

Design and Ergonomics

Handle design for comfort

Snap-On spanner wrenches feature sleek chrome handles. The design prioritizes user comfort. The smooth surface reduces hand fatigue during extended use. The ergonomic handle allows for a secure grip. This design improves overall user experience.

Weight and balance considerations

The weight and balance of Snap-On spanner wrenches are carefully engineered. These factors contribute to ease of use. A well-balanced wrench minimizes strain on the user’s wrist. The optimal weight ensures efficient handling. Users can perform tasks with greater precision.

Precision and Performance

Accuracy in fitting

Snap-On spanner wrenches excel in precision. The Flank Drive Plus profile on the open end enhances grip. This design minimizes slipping. The tool delivers up to 62% more turning power. The accuracy in fitting ensures secure fastener engagement.

Performance in different conditions

Snap-On spanner wrenches perform reliably in various conditions. The 15° offset angle provides more knuckle clearance. This feature offers better accessibility in tight spaces. The wrenches maintain performance even under high torque applications. Users can trust these tools for consistent results.

Benefits of Using Snap-On Spanner Wrenches

Reliability and Trustworthiness

Brand reputation

Snap-On has built a strong reputation over the years. Professionals in various fields trust Snap-On tools. The brand’s history dates back to 1920. Innovation drives the company forward. Snap-On tools are known for their quality and reliability. Many professional shops display Snap-On tools proudly. The brand represents professionalism and excellence.

Customer reviews and testimonials

Customer reviews highlight the reliability of Snap-On spanner wrenches. Professionals from different industries praise these tools. One customer stated, “Generations of professionals respect and trust our tools.” Another review mentioned, “Snap-on tools are used by top motorsports teams because under these conditions, failure is not an option.” These testimonials reflect the high regard for Snap-On tools. The brand continues to earn new business from professionals who value quality.

Versatility and Range

Different sizes and sets available

Snap-On offers a wide range of spanner wrenches. Customers can choose from various sizes and sets. The 10-Piece Ratcheting Open End Box Wrench Set (SRXRM710) is one popular option. This set provides power and performance. Snap-On spanner wrenches cater to different needs. The variety ensures that users find the right tool for any task.

Suitability for various tasks

Snap-On spanner wrenches suit many applications. Mechanics use them for automotive repairs. Construction workers rely on them for assembling structures. Industrial maintenance teams use these wrenches for machinery upkeep. The versatility of Snap-On spanner wrenches makes them ideal for various tasks. Users appreciate the adaptability and efficiency of these tools.

How to Choose the Best Snap-On Spanner Wrench

Assessing Your Needs

Type of Work and Frequency of Use

Identify the type of work that requires a spanner wrench. Automotive repairs, construction projects, and industrial maintenance each have specific needs. Determine how often the tool will be used. Frequent use demands a more durable option. Occasional use may allow for a less robust model.

Specific Requirements and Preferences

Consider any specific requirements for the tasks at hand. Some jobs may need a wrench with a particular jaw design. Others may require a certain size range. Personal preferences also play a role. Some users prefer a lighter tool for ease of handling. Others may prioritize a more ergonomic handle for comfort.

Budget Considerations

Price Range and Value for Money

Evaluate the price range of available Snap-On spanner wrenches. Higher-priced models often offer better features and durability. However, budget constraints may limit options. Look for the best value for money. A mid-range option can provide a good balance between cost and quality.

Warranty and After-Sales Service

Check the warranty offered by Snap-On. A longer warranty period indicates confidence in the product’s durability. Also, consider the after-sales service. Reliable customer support can be crucial if issues arise. Snap-On’s reputation for excellent service adds value to the purchase.

Comparing Models

Key Features to Compare

Compare key features of different Snap-On spanner wrenches. Look at the material used. Special alloy steel provides strength and durability. Examine the handle design. Sleek chrome handles offer comfort and reduce hand fatigue. Evaluate the precision of the tool. The Flank Drive Plus profile enhances grip and turning power.

Pros and Cons of Popular Models

Review the pros and cons of popular Snap-On models. The 10-Piece Ratcheting Open End Box Wrench Set (SRXRM710) offers versatility and performance. Long combination wrenches reduce the number of tools needed. However, some users may prefer standard length wrenches for specific tasks. Weigh these factors to make an informed decision.

Choosing the best Snap-On spanner wrench involves understanding key features and benefits. Assessing specific needs and comparing models ensures an informed decision. Investing in quality tools like Snap-On spanner wrenches enhances performance and longevity.

Final Tips:

- Identify Needs: Match the tool to the type of work and frequency of use.

- Evaluate Features: Consider material, design, and precision.

- Compare Models: Weigh pros and cons for the best fit.

Investing in high-quality tools leads to improved efficiency and job satisfaction. Quality tools reduce errors and save time, boosting overall productivity.