Allen hand tools have become essential in various industries due to their compact size and versatility. Selecting the right type of Allen hand tool ensures efficiency and precision in tasks. The market for these tools continues to grow, driven by the increasing demand for DIY projects and advancements in tool manufacturing. Understanding the importance of choosing the appropriate Allen hand tool can significantly impact the success of any project.

Understanding Allen Hand Tools

What are Allen Hand Tools?

Definition and History

Allen hand tools, also known as hex keys or Allen wrenches, feature a hexagonal cross-section. These tools fit into corresponding screw heads or bolts. The design allows for efficient torque application. William G. Allen founded the Allen Manufacturing Company in 1910 in Hartford, Connecticut. In 1913, Allen introduced the Allen key and the Allen Safety Set Screw. These innovations revolutionized fastening methods in various industries.

Common Uses

Allen hand tools serve multiple purposes. They tighten and loosen hexagonal bolts and screws. Common applications include assembling furniture, maintaining bicycles, and repairing automotive parts. Many industries rely on these tools due to their precision and ease of use.

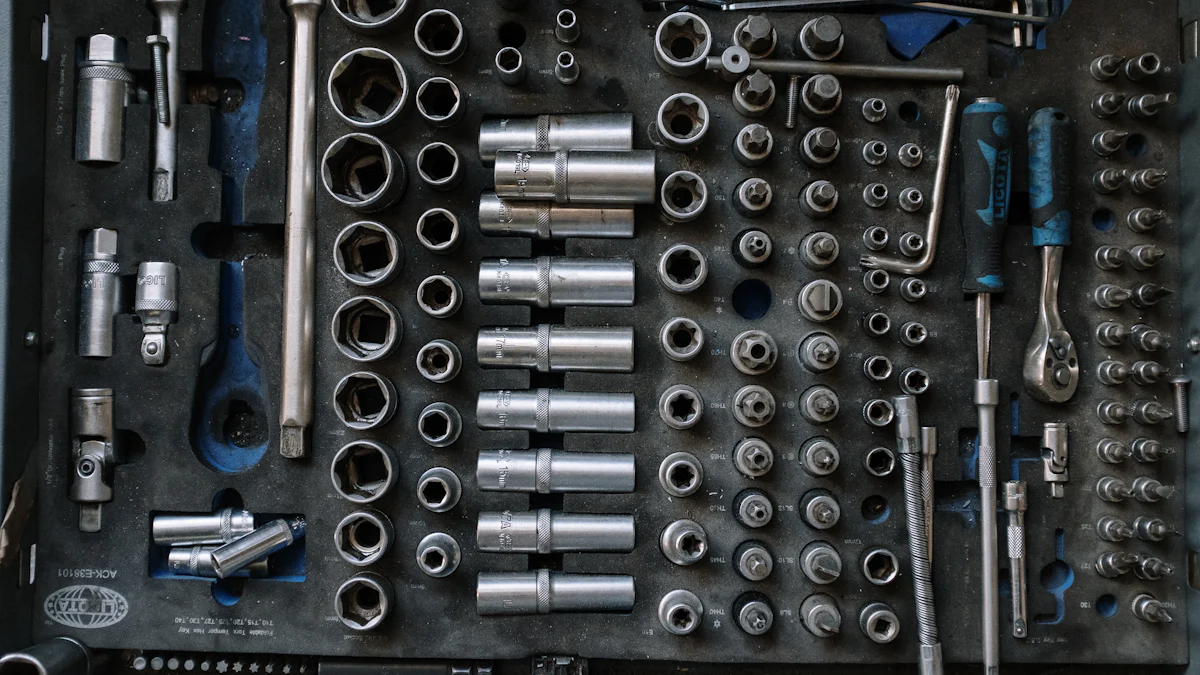

Types of Allen Hand Tools

Hex Wrenches

Hex wrenches, the most basic form of Allen hand tools, come in L-shaped designs. These wrenches provide leverage and torque. Users can choose from different sizes to match specific fasteners. Hex wrenches often come in sets, offering a range of sizes for various tasks.

Allen Keys

Allen keys, another term for hex wrenches, offer similar functionality. These tools fit into hexagonal screw heads and bolts. The compact design makes them easy to carry and store. Allen keys are essential for many DIY projects and professional repairs.

T-Handle Allen Wrenches

T-handle Allen wrenches feature a T-shaped handle. This design provides better grip and control. Users can apply more torque with less effort. T-handle wrenches are ideal for tasks requiring repetitive motion or high torque.

Folding Hex Key Sets

Folding hex key sets resemble pocket knives. These sets contain multiple hex keys of different sizes. The folding design keeps the keys organized and portable. Users can easily switch between sizes without losing individual keys.

Factors to Consider When Choosing Allen Hand Tools

Material and Durability

Steel Types

Allen hand tools come in various steel types. High-carbon steel offers strength and durability. Chrome-vanadium steel provides resistance to wear and corrosion. Stainless steel resists rust, making it ideal for humid environments. Each steel type affects the tool’s longevity and performance.

Coatings and Finishes

Coatings and finishes enhance the durability of Allen hand tools. Black oxide coating prevents rust and corrosion. Chrome plating offers a shiny finish and additional protection. Nickel plating provides a smooth surface and resists wear. Each finish improves the tool’s lifespan and usability.

Size and Fit

Metric vs. Imperial

Allen hand tools come in metric and imperial sizes. Metric sizes measure in millimeters. Imperial sizes measure in inches. The choice depends on the fasteners used in the project. Some projects require both metric and imperial tools for compatibility.

Ensuring Proper Fit

Ensuring a proper fit is crucial for effective use. A loose fit can strip the fastener head. A tight fit provides better torque and control. Users should match the tool size to the fastener size. Proper fit prevents damage and ensures efficient work.

Handle Design and Comfort

Ergonomic Designs

Ergonomic designs improve user comfort. T-handle Allen wrenches offer a comfortable grip. L-shaped wrenches provide leverage in tight spaces. Ergonomic designs reduce hand strain and increase efficiency. Users should choose designs that suit their specific needs.

Grip and Control

Grip and control are essential for precision work. T-handle wrenches offer better grip and control. L-shaped wrenches provide leverage for tight spaces. Users should consider the task requirements. Proper grip and control enhance the tool’s effectiveness.

Practical Applications and User Tips

Common Projects and Uses

Furniture Assembly

Allen hand tools play a crucial role in furniture assembly. Many flat-pack furniture kits include hexagonal bolts and screws. Allen wrenches provide the necessary torque to secure these fasteners. The compact design of Allen keys allows for easy maneuvering in tight spaces. Users can efficiently assemble chairs, tables, and shelves with these tools.

Bicycle Maintenance

Bicycle maintenance often requires the use of Allen hand tools. Hex wrenches are essential for adjusting bike components. Cyclists use them to tighten or loosen bolts on handlebars, seats, and brakes. The precise fit of Allen keys ensures that components remain securely fastened. Regular maintenance with these tools can extend the lifespan of a bicycle.

Automotive Repairs

Automotive repairs frequently involve Allen hand tools. Mechanics use hex wrenches to work on various car parts. These tools are ideal for tasks such as adjusting engine components and securing interior fixtures. The ability to apply significant torque makes Allen keys valuable in automotive settings. Proper use of these tools can enhance the performance and safety of a vehicle.

Maintenance and Care

Cleaning and Storage

Proper cleaning and storage of Allen hand tools ensure their longevity. Users should clean tools after each use to remove dirt and debris. A dry cloth can wipe down the surface of the wrenches. Storing tools in a dry environment prevents rust and corrosion. Organizing tools in a dedicated toolbox or case keeps them accessible and protected.

Preventing Wear and Tear

Preventing wear and tear extends the life of Allen hand tools. Users should avoid applying excessive force to prevent bending or breaking. Using the correct size for each fastener reduces the risk of damage. Regular inspection of tools helps identify signs of wear. Replacing worn-out tools maintains the efficiency and safety of any project.

The blog highlighted the key aspects of Allen hand tools. These tools offer versatility, durability, and precision. The various types, such as hex wrenches and T-handle wrenches, cater to different needs. Material and design play crucial roles in performance and comfort.

Choosing the best Allen hand tool depends on specific project requirements. High-quality materials and ergonomic designs enhance user experience. The right tool ensures efficiency and accuracy.

Applying this knowledge in real-world scenarios will improve project outcomes. Allen hand tools remain indispensable for both professionals and DIY enthusiasts.