Choosing the right cut out tool bits is crucial for drywall projects. These bits ensure precise and efficient cuts, which enhance the overall quality of work. High-quality options like Rotozip and Montana Brand bits offer reliability and durability. Spiral upcut and downcut bits provide fast and clean cuts, making them ideal for drywall applications. Investing in the right bits saves time and money in the long run. Professional users often prefer routers for their speed and accuracy. A well-chosen bit can significantly improve the outcome of any drywall project.

Types of Cut Out Tool Bits

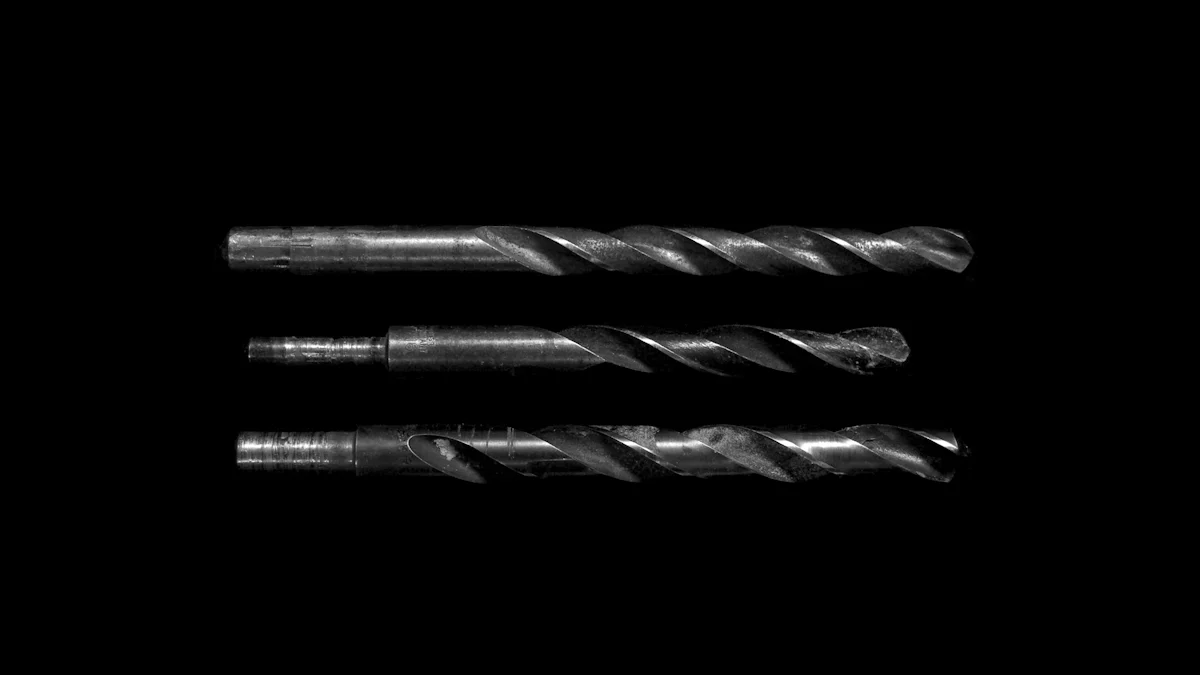

Spiral Upcut Bits

Applications and Benefits

Spiral upcut bits excel in drywall projects. These bits remove material quickly, which results in clean edges. The design of spiral upcut bits helps in reducing the risk of overheating. RotoZip Drywall Router uses these bits for guiding cuts. This tool works well for larger projects due to its power and precision.

Best Practices for Use

Users should maintain a steady hand when using spiral upcut bits. A consistent speed ensures smooth cuts. Users should avoid applying excessive pressure to prevent bit breakage. Regular inspection of the bit’s condition helps maintain performance. Proper storage after use extends the lifespan of the bit.

Spiral Downcut Bits

Applications and Benefits

Spiral downcut bits provide excellent control during cuts. These bits minimize chipping on the surface of drywall. The ToolPro 3/16 in. Piloted Down Spiral Cutout Bit offers longer durability. This heavy-duty bit ensures precise cuts, making it ideal for professional applications.

Best Practices for Use

Users should start with a lower speed setting when using spiral downcut bits. Gradually increasing speed enhances control. Keeping the bit cool prevents overheating. Users should clean the bit after each use to maintain cutting efficiency. Proper maintenance ensures long-lasting performance.

Other Types of Bits

Specialty Bits

Specialty bits cater to specific drywall tasks. Standard Point Cut-Out Bit by DeWalt provides high-accuracy cuts. This bit suits extended use in drywall and gypsum board. Seamless and controlled cutting makes it reliable for professionals.

Multi-purpose Bits

Multi-purpose bits offer versatility in drywall projects. These bits handle various materials beyond drywall. Users benefit from the flexibility of multi-purpose bits. Investing in quality multi-purpose bits saves time and effort. These bits adapt to different cutting needs efficiently.

Top Brands and Products

Rotozip

Key Features

RotoZip offers robust cut out tool bits for drywall projects. The RotoZip GP50 1/8” Drywall Rotary Bit stands out for its durability. This bit handles tough drywall tasks with ease. Users appreciate the long-lasting performance of these bits. The RotoZip 1/8” ZB50 is another popular choice. This original ZipBit excels in making precise drywall cut-outs.

Unique Selling Points

RotoZip bits ensure reliable and efficient cutting. The design reduces the risk of overheating during use. Professionals favor these bits for their consistent results. RotoZip products provide excellent value for money. The brand’s reputation for quality makes it a top choice for drywall projects.

Montana Brand

Key Features

Montana Brand specializes in high-performance cut out tool bits. The CNC drywall cutout bits deliver exceptional results. These bits are engineered for demanding construction tasks. Users find them perfect for cutting electrical boxes and window openings. Montana Brand bits offer precision and reliability.

Unique Selling Points

Montana Brand focuses on versatility and durability. The bits perform well in various drywall applications. Users benefit from the smooth and accurate cuts these bits provide. Montana Brand products cater to both professionals and DIY enthusiasts. The brand’s commitment to quality ensures customer satisfaction.

Dremel

Key Features

Dremel Rotary Tools offer versatile solutions for multiple tasks. These tools excel in drilling, cutting, and sanding. Dremel’s cut out tool bits work efficiently on drywall. The bits ensure clean and fast cuts, enhancing project quality. Users appreciate the adaptability of Dremel tools for diverse projects.

Unique Selling Points

Dremel tools stand out for their versatility. The bits handle a wide range of materials beyond drywall. Users enjoy the flexibility in switching between tasks. Dremel’s reputation for innovation attracts many users. The brand’s tools provide excellent support for DIY projects.

Product Comparison

Feature Comparison

Durability

Durability plays a crucial role in selecting cut out tool bits. High-speed steel (HSS) is a common material for these bits. HSS offers excellent durability for most drywall projects. Carbide and cobalt steel provide even greater durability. These materials withstand heavy use without losing sharpness. Professionals often choose carbide for demanding tasks. The longevity of a bit depends on its material composition. Regular maintenance also extends the lifespan of any bit.

Versatility

Versatility enhances the value of cut out tool bits. Multi-purpose bits handle various materials with ease. Users benefit from the adaptability of these bits. Dremel tools offer great versatility for different tasks. These tools switch between drilling, cutting, and sanding effortlessly. RotoZip bits excel in making precise drywall cut-outs. Montana Brand bits perform well in multiple drywall applications. Versatile bits save time and effort in diverse projects.

Price Comparison

Budget Options

Budget options provide cost-effective solutions for users. High-speed steel bits offer affordability and reliability. Users find these bits suitable for standard drywall tasks. Dremel provides budget-friendly choices for DIY enthusiasts. These options deliver satisfactory performance at a lower cost. Investing in budget bits helps manage project expenses effectively.

Premium Options

Premium options cater to professional needs. Carbide and cobalt steel bits fall into this category. These bits offer superior durability and precision. RotoZip and Montana Brand provide high-end products for experts. Users appreciate the consistent results from premium bits. Investing in premium options ensures long-lasting performance. Professionals prefer these bits for demanding drywall projects.

Practical Tips for Effective and Safe Use

Usage Tips

Safety Precautions

Safety should always come first when working with cut out tool bits. Wear protective eyewear to shield your eyes from flying debris. Gloves can protect your hands from sharp edges and vibrations. Ensure the work area is well-lit to avoid mistakes. Keep a firm grip on the tool to maintain control during operation. Always unplug the tool before changing bits to prevent accidents.

Efficiency Tips

Efficiency improves the quality of your drywall projects. Choose the right bit for the specific task to ensure clean cuts. Maintain a steady speed to avoid overheating the bit. Regularly inspect the bit for wear and tear to maintain performance. Use a guide or template for straight cuts to enhance precision. Practice on scrap material to gain confidence and improve skills.

Maintenance and Care

Cleaning Tips

Proper cleaning extends the lifespan of your tool bits. Remove dust and debris from the bit after each use. Use a soft brush or cloth to clean the bit without damaging it. Avoid using harsh chemicals that can corrode the bit. Dry the bit thoroughly to prevent rust formation. Store the bit in a dry place to maintain its condition.

Storage Tips

Correct storage prevents damage to your tool bits. Use a dedicated case or holder to organize the bits. Label each compartment to easily find the right bit. Avoid stacking bits on top of each other to prevent chipping. Keep the storage area free from moisture to avoid rust. Regularly check the storage conditions to ensure the bits remain in good shape.

Selecting the right tool bits is crucial for achieving precise drywall cuts. Proper tool selection enhances project quality and efficiency. Applying practical tips ensures optimal results. Consistent speed and steady hands improve cutting performance. Regular maintenance and care extend tool longevity. Cleaning and proper storage prevent rust and damage. Investing in quality bits saves time and money. Sharpening tools maintains their effectiveness. Using cutting fluid prolongs tool life. Understanding tool craftsmanship adds value to your skills. Mastering these practices leads to successful drywall projects.