Choosing the right door cutting tool holds great importance for any project. A precise cut ensures a perfect fit and a professional finish. The market offers a wide variety of tools, each designed for specific tasks. Careful selection becomes crucial to match the tool with your needs. Recent data shows a significant increase in cutting tool shipments, reaching $214.4 million in May 2024. This growth highlights the demand for effective tools. Understanding the available options helps you make informed decisions.

Understanding Door Cutting Tools

Choosing the right door cutting tool involves understanding the different types available. Each tool serves a specific purpose and offers unique advantages.

Types of Door Cutting Tools

Manual Tools

Manual tools provide precision and control. A hand saw or plane works well for minor adjustments. These tools require physical effort but offer accuracy for small tasks. Many professionals prefer manual tools for delicate work on wooden doors.

Power Tools

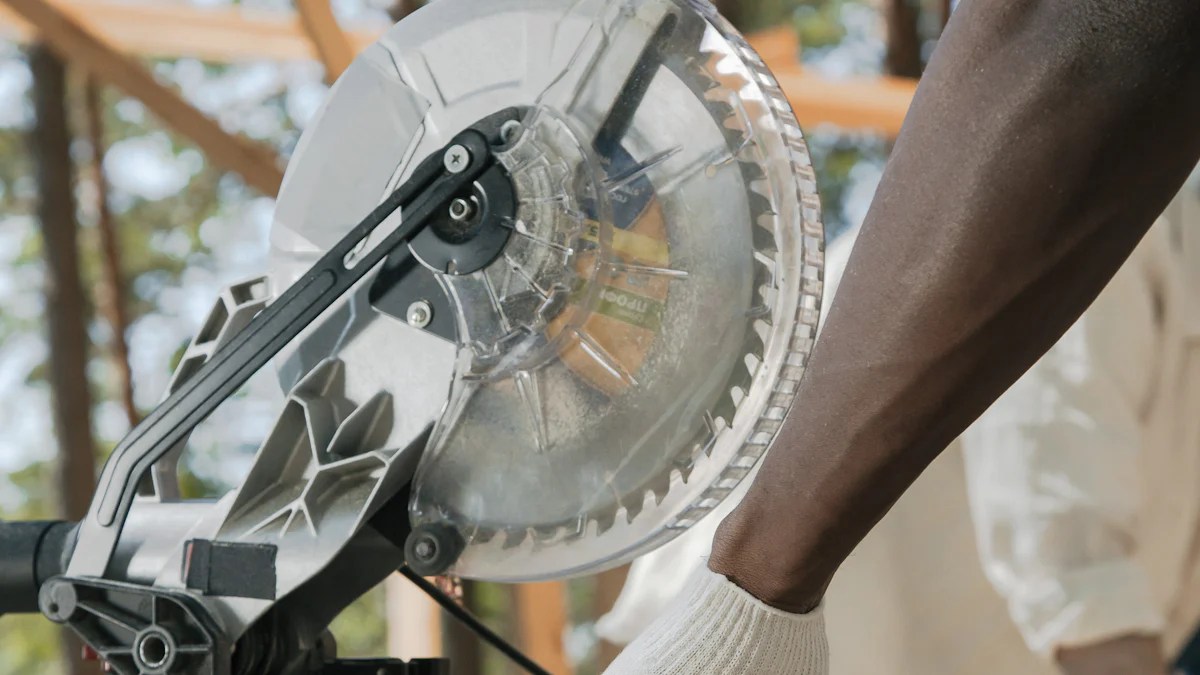

Power tools offer speed and efficiency. A circular saw with a straight edge delivers a perfect straight cut in one pass. This tool suits larger cuts and saves time. The RYOBI Wood Door Trimmer stands out as a convenient option. This trimmer requires only a standard drill to shave off excess material. The door remains on-hinge, reducing project time and effort.

Key Features to Consider

Selecting the best door cutting tool involves evaluating key features. These features determine the tool’s effectiveness and suitability for your needs.

Blade Material

Blade material affects the quality of the cut. A carbide-tipped blade with 24 to 40 teeth provides a nice cut. This blade type works well for general use and ensures a clean finish. Sharp blades prevent splintering and maintain the door’s appearance.

Cutting Capacity

Cutting capacity refers to the tool’s ability to handle different door sizes. Some tools trim up to 1/32″ per pass on 1-3/4″ & 1-3/8″ size doors. This feature is crucial for projects involving various door dimensions. Ensure the tool matches the specific requirements of your door.

Ease of Use

Ease of use enhances the overall experience with the door cutting tool. Tools like the RYOBI Wooden Door Trimmer simplify the process. This trimmer eliminates the need for bulky sanders and planers. User-friendly tools reduce fatigue and increase efficiency.

Understanding these aspects helps you choose the right door cutting tool for your project. Evaluate each feature carefully to ensure the tool meets your expectations.

Assessing Your Needs

Type of Door Material

Wood

Wooden doors require specific cutting tools for a clean finish. A hand plane or a circular saw with a fine-toothed blade works well. These tools provide precision and control for wooden surfaces. The RYOBI Wood Door Trimmer offers an efficient solution. This tool uses a standard drill to remove up to 1/32″ per pass. This method reduces project time and effort.

Metal

Metal doors demand robust tools for effective cutting. A jigsaw or a metal-cutting circular saw suits this task. These tools handle the density and strength of metal materials. A carbide-tipped blade enhances the cutting process. This blade type ensures smooth edges without damaging the door.

Composite

Composite doors combine various materials. A skilsaw or a plunge cut circular saw performs well on composite doors. These tools offer versatility for different textures and densities. Masking tape over the cut line helps reduce splintering. This technique maintains the door’s appearance.

Type of Cut Required

Straight Cuts

Straight cuts need precision and accuracy. A circular saw with a straight edge guide provides a perfect straight cut. This setup ensures a clean line in one pass. Scoring the cut line with a utility knife prevents splintering. A sharp blade with at least 18 teeth enhances the quality of the cut.

Curved Cuts

Curved cuts require flexibility and control. A jigsaw offers the best solution for curved lines. This tool allows maneuverability around curves and shapes. Adjusting the blade speed helps achieve a smooth finish. Proper technique ensures the integrity of the door’s design.

Making the Right Choice

Budget Considerations

Cost vs. Quality

Selecting a door cutting tool requires balancing cost and quality. A high-quality tool often provides better performance and durability. Investing in a reliable tool saves money in the long run. A cheaper tool may need frequent replacements or repairs. Consider the tool’s features and materials. A carbide-tipped blade, for example, offers a clean cut and lasts longer.

Long-term Investment

Think about the long-term benefits of your purchase. A durable tool reduces the need for replacements. This saves both time and money. A well-made tool enhances your work quality. A tool that performs well increases efficiency. Consider future projects when choosing a tool. A versatile tool adapts to various tasks and materials.

Brand and Warranty

Reputable Brands

Choose a tool from a reputable brand. Well-known brands often provide better quality and support. These brands invest in research and development. This leads to innovative and reliable products. A trusted brand ensures you receive a high-performing tool. Look for customer reviews and expert recommendations. These sources offer valuable insights into a brand’s reputation.

Warranty and Support

A good warranty provides peace of mind. A warranty protects your investment against defects. Manufacturers with strong warranties show confidence in their products. Customer support is also important. Reliable support helps resolve issues quickly. Check the warranty terms before purchasing a tool. A comprehensive warranty indicates a commitment to quality.

Selecting the right door cutting tool ensures a professional finish. A precise tool choice prevents chipping and splintering. Consider your specific needs and preferences. Evaluate the type of material and cut required. Invest in quality tools for long-term benefits. A user on a forum shared, “A circular saw with a fine tooth blade and masking tape prevents tearout.” This advice highlights the importance of proper tool selection. Make informed decisions by considering factors like blade material and cutting capacity. The right tool enhances efficiency and work quality.