Using a torque wrench correctly ensures precise fastening and prevents structural damage. The 3/4 torque wrench, known for its power and accuracy, is essential in various applications such as automotive repair and heavy machinery maintenance. This blog provides essential tips for effective use, ensuring optimal performance and longevity.

Understanding Your 3/4 Inch Torque Wrench

Components of a 3/4 Inch Torque Wrench

Handle

The handle of a 3/4 torque wrench provides the necessary leverage to apply torque. Most handles feature an ergonomic design to ensure a comfortable grip. High-quality models, such as the Performance Tool M203, include a locking mechanism to prevent accidental adjustments during use.

Drive

The drive connects the wrench to the socket. A 3/4 inch drive is robust and suitable for heavy-duty applications. This component must fit securely with the socket to ensure accurate torque application.

Scale

The scale displays the torque setting. Users must read the scale accurately to set the desired torque. Some models, like the CDI Click Type Wrench, offer precise adjustments for enhanced accuracy.

How a 3/4 Inch Torque Wrench Works

Mechanism

A 3/4 torque wrench operates through a mechanical mechanism. When users apply force, the wrench clicks to indicate the desired torque level has been reached. This click provides an audible signal, ensuring users do not over-tighten fasteners.

Calibration

Calibration ensures the wrench delivers accurate torque readings. Regular calibration checks are essential. Users must follow the manufacturer’s guidelines to maintain the wrench’s accuracy. The Performance Tool M203 includes features that help maintain its calibration over time.

Preparing for Use

Checking Calibration

Importance of Calibration

Calibration ensures that a 3/4 torque wrench delivers precise torque readings. Regular calibration checks are essential to maintain accuracy. Accurate torque application prevents structural damage and ensures the longevity of fasteners. Studies show that regular calibration is crucial for maintaining tool precision. An accredited laboratory can provide reliable calibration services.

How to Check Calibration

To check calibration, follow the manufacturer’s guidelines. Use a calibrated torque tester to compare the wrench’s readings against known values. Adjust the wrench if discrepancies are found. Regular checks prevent errors and ensure consistent performance. Proper calibration safeguards the accuracy of the 3/4 torque wrench.

Setting the Desired Torque

Reading the Scale

Reading the scale accurately is vital for setting the desired torque. The scale on a 3/4 torque wrench displays the torque setting in units such as foot-pounds or Newton-meters. Align the pointer with the desired value. Ensure that the reading is clear and precise. Some models offer digital displays for enhanced accuracy.

Adjusting the Torque

Adjust the torque by turning the handle or dial. Set the wrench to the lowest setting when not in use to reduce tension. Practice setting the torque to become familiar with the wrench’s operation. Avoid exceeding the wrench’s range to prevent damage. Proper adjustment ensures accurate torque application and prolongs the tool’s lifespan.

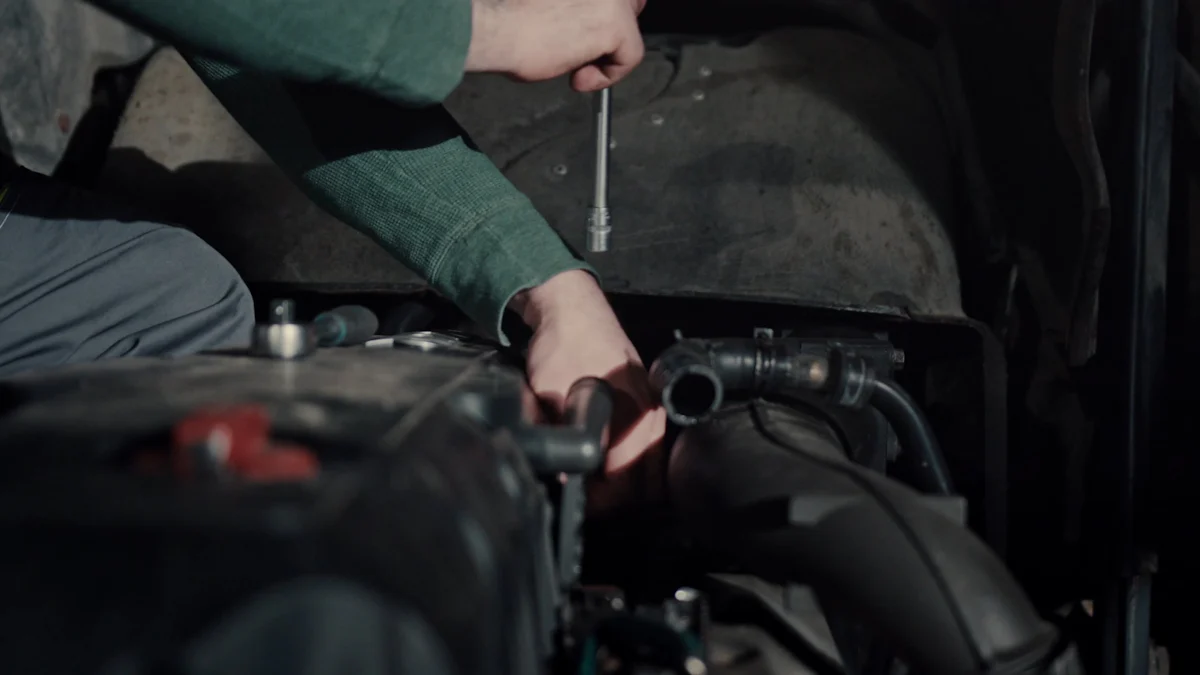

Using the 3/4 Inch Torque Wrench

Proper Handling Techniques

Grip

A firm grip on the handle of a 3/4 torque wrench ensures precise control. Users should wrap their fingers around the handle, maintaining a comfortable yet secure hold. The ergonomic design of most handles, such as those found on high-quality models like the Performance Tool M203, provides comfort during prolonged use. A proper grip reduces the risk of slippage and enhances accuracy.

Positioning

Correct positioning is crucial for effective torque application. Users should align their body with the fastener, ensuring that the wrench remains perpendicular to the bolt or nut. This alignment prevents angular force, which can lead to inaccurate torque readings. Maintaining a stable stance with feet shoulder-width apart provides balance and control. Proper positioning minimizes strain and maximizes efficiency.

Applying Torque

Steady Pressure

Applying steady pressure is essential when using a 3/4 torque wrench. Users should apply force smoothly and gradually until the wrench clicks. This click indicates that the desired torque level has been reached. Sudden or jerky movements can result in inaccurate torque application. Consistent pressure ensures that the fastener receives the correct amount of torque, preventing damage and ensuring safety.

Avoiding Over-Tightening

Over-tightening can cause significant damage to both the fastener and the component. Users must stop applying force immediately after hearing the click from the 3/4 torque wrench. Continuing to tighten beyond this point can strip threads or break bolts. Practicing restraint and listening for the click ensures that fasteners are secured correctly without being over-torqued.

Maintenance and Storage

Cleaning the Torque Wrench

After Each Use

Clean a 3/4 torque wrench with a dry cloth after each use to remove dirt and grease. This practice prevents debris from accumulating on the tool, which can affect its performance. Regular cleaning ensures that the wrench remains in optimal condition for accurate torque application.

Periodic Deep Cleaning

Perform periodic deep cleaning to maintain the efficiency of a 3/4 torque wrench. Disassemble the wrench according to the manufacturer’s instructions. Clean each component thoroughly using appropriate cleaning agents. Ensure all parts are dry before reassembling the wrench. This process helps in removing any stubborn grime that regular cleaning might miss.

Storing the Torque Wrench

Proper Storage Conditions

Store a 3/4 torque wrench in a protective case to prevent damage. Follow the manufacturer’s guidelines for storage to avoid compromising the tool’s spring mechanism. Keeping the wrench in a controlled environment, away from moisture and extreme temperatures, preserves its accuracy and longevity.

“Equipped storage: Always store your torque wrench in a protective case and follow manufacturers guidelines for storage to prevent damage to the spring, if stored for long periods of time.” – HTL Group

Avoiding Damage

Return the 3/4 torque wrench to its lowest setting after each job. This step reduces stress on the internal components, particularly the spring. Avoid using extension handles or additional levers with the wrench. These practices ensure that the wrench remains in good working condition and provides accurate torque readings.

“Maintaining the precision and durability of your torque wrench requires proper storage techniques. Don’t forget to wind back the torque setting when the tool isn’t in use. This easy step reduces stress on the internal components, specifically the spring, which can deteriorate with continued tension.” – Microprecision

A 3/4 torque wrench requires proper usage and maintenance for optimal performance. Adhering to essential tips ensures accurate torque application and prevents damage. Regular calibration checks maintain precision. Cleaning the tool after each use removes debris. Proper storage conditions preserve the wrench’s functionality. Users should practice correct handling techniques. Applying steady pressure avoids over-tightening. Following these guidelines extends the lifespan of the 3/4 torque wrench. Professional mechanics emphasize the importance of these practices. Proper care guarantees reliable and safe operation.

See Also

Cruising Tool: Best Upgrades for Mopeds