Having the right cutting tools is crucial for efficiency and precision in any project. Champion Cutting Tool Corp, a company with over 120 years of history, remains committed to creating innovative, problem-solving tools. The brand offers a wide range of high-quality tools designed to increase productivity and ensure availability when needed. Transitioning into the top five tools offered by Champion Cutting Tool will highlight the essential products that can enhance various cutting tasks.

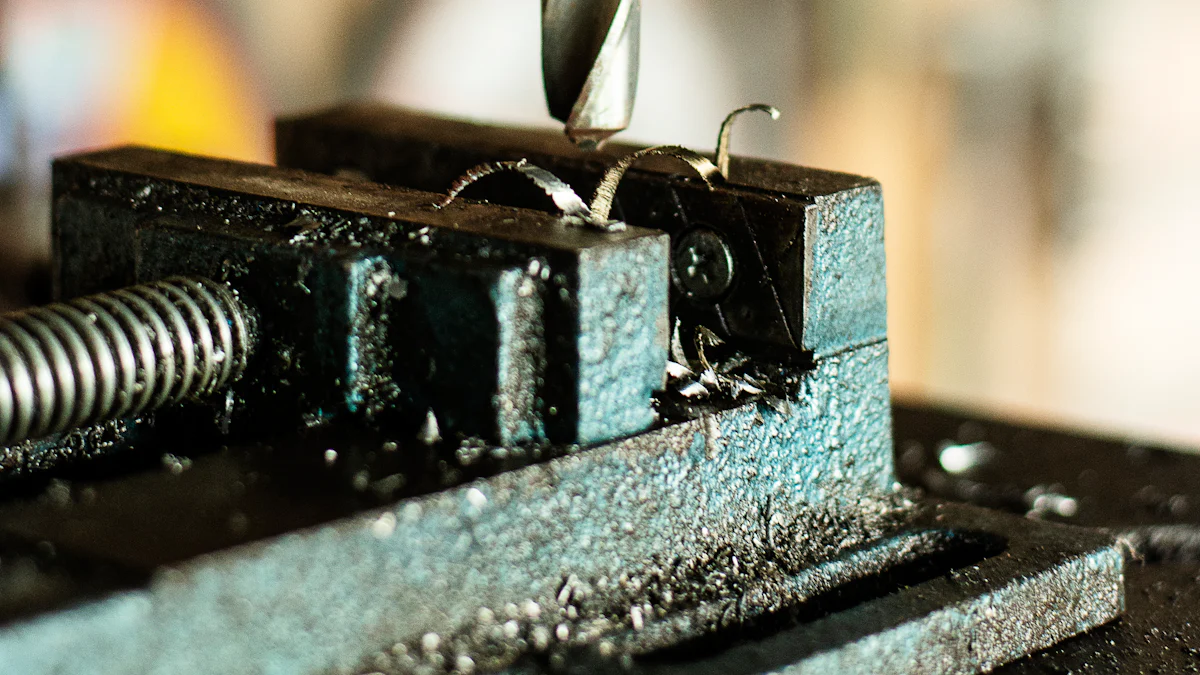

1. Twist Drills

Description

What are Twist Drills?

Twist drills represent a fundamental tool in the arsenal of any machinist or DIY enthusiast. These tools feature a helical flute design that efficiently removes material from the workpiece. The twist drill’s primary function involves creating cylindrical holes in various materials, including metal, wood, and plastic.

Key Features

- High Performance: Champion Cutting Tool manufactures twist drills designed for high performance and durability.

- Versatility: These drills can handle tasks like drilling, reaming, cutting, and tapping.

- Adaptability: The QX1234 Drill/Chuck Adapter allows for easy conversion from annular cutters to twist drills.

- Extended Tool Life: The design of these drills reduces chip welding, extending the tool’s lifespan.

- Sharp Teeth: Sharp teeth ensure productive drilling and efficient material removal.

Applications

Common Uses

Twist drills find applications in several common tasks:

- Metal Drilling: Ideal for creating precise holes in metal surfaces.

- Woodworking: Useful for drilling clean holes in wood projects.

- Plastic Fabrication: Effective in creating holes in plastic materials.

Industries Benefiting from Twist Drills

Several industries benefit significantly from using twist drills:

- Manufacturing: Essential for producing components with precise holes.

- Construction: Useful for creating holes in various building materials.

- Automotive: Important for drilling tasks in vehicle assembly and repair.

- Aerospace: Critical for precision drilling in aircraft manufacturing.

Champion Cutting Tool ensures that their twist drills meet the high standards required across these diverse applications. The versatility and durability of these tools make them indispensable in many professional settings.

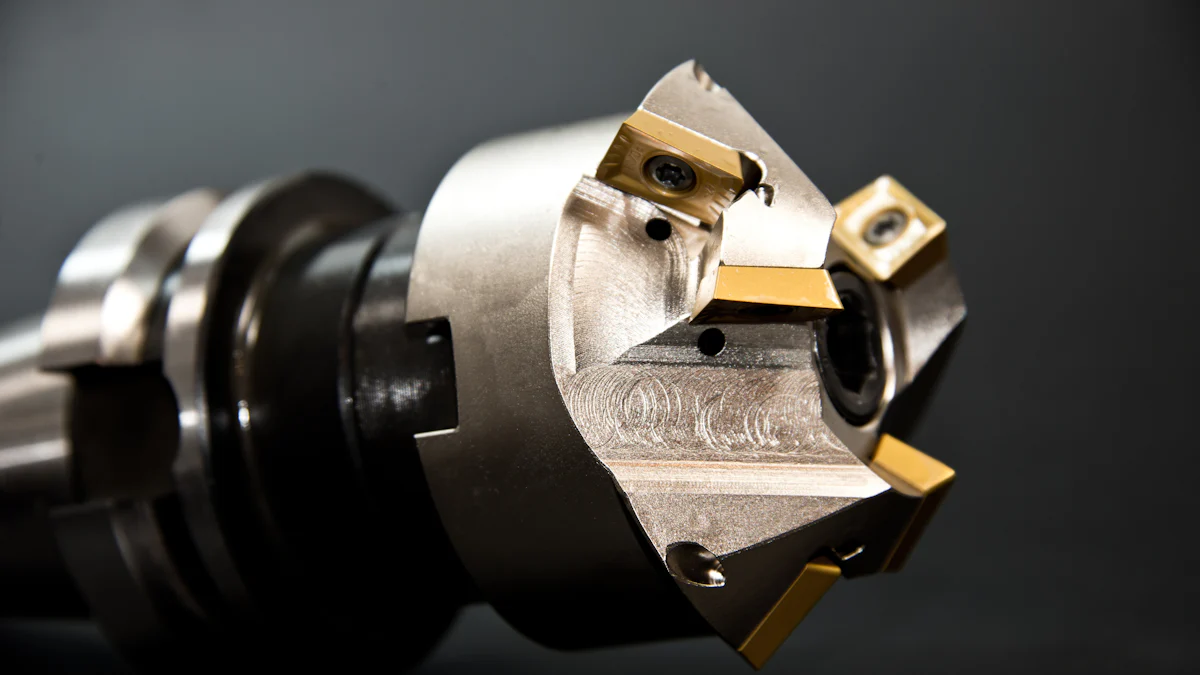

2. Annular Cutters

Description

What are Annular Cutters?

Annular cutters, also known as core drills, create precise holes by removing a cylindrical piece of material. Champion Cutting Tool designs these tools with a hollow center, which reduces the amount of material removed. This design increases efficiency and reduces wear on the tool. Annular cutters excel in creating larger diameter holes compared to twist drills.

Key Features

- Efficiency: Annular cutters remove less material, resulting in faster drilling times.

- Durability: Champion Cutting Tool manufactures annular cutters with high-quality materials for extended tool life.

- Precision: The design ensures accurate hole dimensions and smooth finishes.

- Versatility: These tools can handle various materials, including metal, wood, and plastic.

- Ease of Use: The hollow center allows for easy removal of the core, simplifying the drilling process.

Applications

Common Uses

Annular cutters find applications in numerous tasks:

- Metal Fabrication: Ideal for creating clean and precise holes in metal sheets and plates.

- Construction Projects: Useful for drilling through structural steel and other building materials.

- Pipe Installation: Effective in creating holes for pipe fittings and installations.

- Maintenance Work: Suitable for repair and maintenance tasks requiring precise hole creation.

Industries Benefiting from Annular Cutters

Several industries benefit significantly from using annular cutters:

- Manufacturing: Essential for producing components with exact hole specifications.

- Construction: Valuable for creating holes in beams, columns, and other structural elements.

- Automotive: Important for drilling tasks in vehicle assembly and repair.

- Aerospace: Critical for precision drilling in aircraft manufacturing.

Champion Cutting Tool ensures that annular cutters meet the high standards required across these diverse applications. The efficiency and precision of these tools make them indispensable in many professional settings.

3. Carbide Burs

Description

What are Carbide Burs?

Carbide burs serve as essential tools for material removal and shaping. Champion Cutting Tool manufactures these burs with high-quality carbide, ensuring durability and performance. The unique Titanium Nitride Coating enhances the tool’s lifespan and efficiency. Carbide burs excel in tasks requiring precise cutting and grinding.

Key Features

- Durability: Champion Cutting Tool uses carbide material for extended tool life.

- Efficiency: The Titanium Nitride Coating reduces wear and increases cutting speed.

- Versatility: Suitable for various materials, including metal, wood, and plastic.

- Precision: Sharp cutting edges ensure accurate material removal.

- Heat Resistance: The coating helps maintain tool integrity at high temperatures.

Applications

Common Uses

Carbide burs find applications in numerous tasks:

- Deburring: Ideal for removing sharp edges and burrs from metal parts.

- Shaping: Useful for sculpting and shaping materials in woodworking and metalworking.

- Grinding: Effective in smoothing surfaces and refining details.

- Engraving: Suitable for detailed engraving work on various materials.

Industries Benefiting from Carbide Burs

Several industries benefit significantly from using carbide burs:

- Manufacturing: Essential for precision deburring and shaping tasks.

- Automotive: Important for refining and detailing vehicle components.

- Aerospace: Critical for high-precision material removal in aircraft manufacturing.

- Dental: Valuable for dental labs in creating and refining prosthetics.

Champion Cutting Tool ensures that carbide burs meet the high standards required across these diverse applications. The combination of durability, efficiency, and precision makes these tools indispensable in many professional settings.

4. Hole Saws

Description

What are Hole Saws?

Hole saws, also known as hole cutters, create circular holes in various materials. Champion Cutting Tool designs these tools with a cylindrical saw blade and an arbor. The arbor attaches to a drill, allowing the saw to cut through the material. Hole saws excel in creating large diameter holes with precision.

Key Features

- Durable Construction: Champion Cutting Tool uses high-quality materials for long-lasting performance.

- Efficient Cutting: The design ensures fast and smooth cutting through different materials.

- Versatile Sizes: Hole saws come in various diameters to suit different project needs.

- Easy Core Removal: The open-back design allows for quick and easy removal of the cut core.

- Compatibility: These tools work with standard drills, making them accessible for many users.

Applications

Common Uses

Hole saws find applications in several tasks:

- Electrical Work: Ideal for creating holes for wiring and electrical boxes.

- Plumbing: Useful for drilling holes for pipes and fittings.

- HVAC Installation: Effective in creating openings for ductwork and vents.

- Woodworking: Suitable for making holes in wood for various projects.

Industries Benefiting from Hole Saws

Several industries benefit significantly from using hole saws:

- Construction: Essential for creating precise holes in building materials.

- Manufacturing: Valuable for producing components with specific hole dimensions.

- Automotive: Important for drilling tasks in vehicle assembly and customization.

- Home Improvement: Useful for DIY projects and renovations requiring accurate hole creation.

Champion Cutting Tool ensures that hole saws meet the high standards required across these diverse applications. The combination of durability, efficiency, and versatility makes these tools indispensable in many professional settings.

5. Countersinks

Description

What are Countersinks?

Countersinks create conical holes that allow screws to sit flush with or below the surface of a material. Champion Cutting Tool designs these tools to produce precise and clean countersunk holes. The primary function involves enlarging the top part of an existing hole to accommodate the screw head.

Key Features

- Precision Cutting: Countersinks from Champion Cutting Tool provide accurate and smooth finishes.

- Durability: High-quality materials ensure long-lasting performance.

- Versatility: Suitable for various materials, including metal, wood, and plastic.

- Ease of Use: The design allows for effortless operation and minimal user fatigue.

- Multiple Sizes: Available in different diameters to match various screw sizes.

Applications

Common Uses

Countersinks find applications in several tasks:

- Woodworking: Ideal for creating countersunk holes for screws in wood projects.

- Metalworking: Useful for preparing metal surfaces for flat-head screws.

- Plastic Fabrication: Effective in creating clean countersunk holes in plastic materials.

- Furniture Making: Essential for assembling furniture pieces with hidden screws.

Industries Benefiting from Countersinks

Several industries benefit significantly from using countersinks:

- Construction: Essential for securing screws in building materials.

- Manufacturing: Valuable for producing components with countersunk holes.

- Automotive: Important for ensuring screws sit flush in vehicle assembly.

- Aerospace: Critical for creating precise countersunk holes in aircraft manufacturing.

Champion Cutting Tool ensures that countersinks meet the high standards required across these diverse applications. The combination of precision, durability, and versatility makes these tools indispensable in many professional settings.

Champion Cutting Tool products offer unmatched durability, precision, and efficiency. These tools enhance productivity in various industries, including manufacturing, construction, automotive, and aerospace. Champion Cutting Tool ensures high-quality performance for every project. Consider incorporating these essential tools into your toolkit. Elevate your work with the reliability and innovation that Champion Cutting Tool provides.

See Also

Scooter Upgrades: High-Quality Parts for Maximum Performance

Winter Bliss: Snug Comfort with Soft Towel Socks

Dive into Diverse Sock Options for Both Genders