Mastering the heavy-duty circle cutter transforms any workshop into a precision powerhouse. The circle cut tool offers unparalleled accuracy, making it indispensable for projects involving sheet metal, wood, or plastic. Using a drill press enhances this precision, ensuring clean and consistent cuts every time. This guide will provide essential tips and techniques to help users achieve professional results with their circle cut tool.

Safety Guidelines

Safety remains paramount when using a heavy-duty circle cutter with a drill press. Adhering to safety guidelines ensures not only the longevity of the equipment but also the well-being of the operator.

Personal Protective Equipment (PPE)

Eye Protection

Operators must wear safety goggles to protect their eyes from flying debris. The cutting process can generate small particles that pose a significant risk to the eyes. Safety goggles provide a barrier against these hazards, ensuring clear vision throughout the task.

Hearing Protection

The noise generated by a drill press can reach harmful levels. Earplugs or earmuffs should be worn to prevent hearing damage. Consistent exposure to high noise levels can lead to long-term hearing loss, making hearing protection essential.

Gloves and Clothing

Proper gloves offer protection against sharp edges and hot surfaces. Operators should choose gloves that provide a good grip without sacrificing dexterity. Loose clothing should be avoided as it can get caught in the machinery. Wearing fitted clothing reduces the risk of accidents.

Tool and Workspace Safety

Securing the Workpiece

Securing the workpiece is crucial for achieving precise cuts. Clamps or vices should be used to hold the material firmly in place. A stable workpiece prevents movement during the cutting process, ensuring accuracy and safety.

Maintaining a Clean Workspace

A clean workspace minimizes the risk of accidents. Debris and tools scattered around the work area can cause tripping hazards. Regularly cleaning the workspace keeps the environment safe and organized.

Proper Handling of the Circle Cutter

Proper handling of the circle cut tool ensures both safety and precision. Operators should always follow the manufacturer’s instructions. The tool should be inspected before each use to ensure it is in good working condition. Proper handling techniques reduce the risk of injury and improve the quality of the cuts.

Precision Techniques

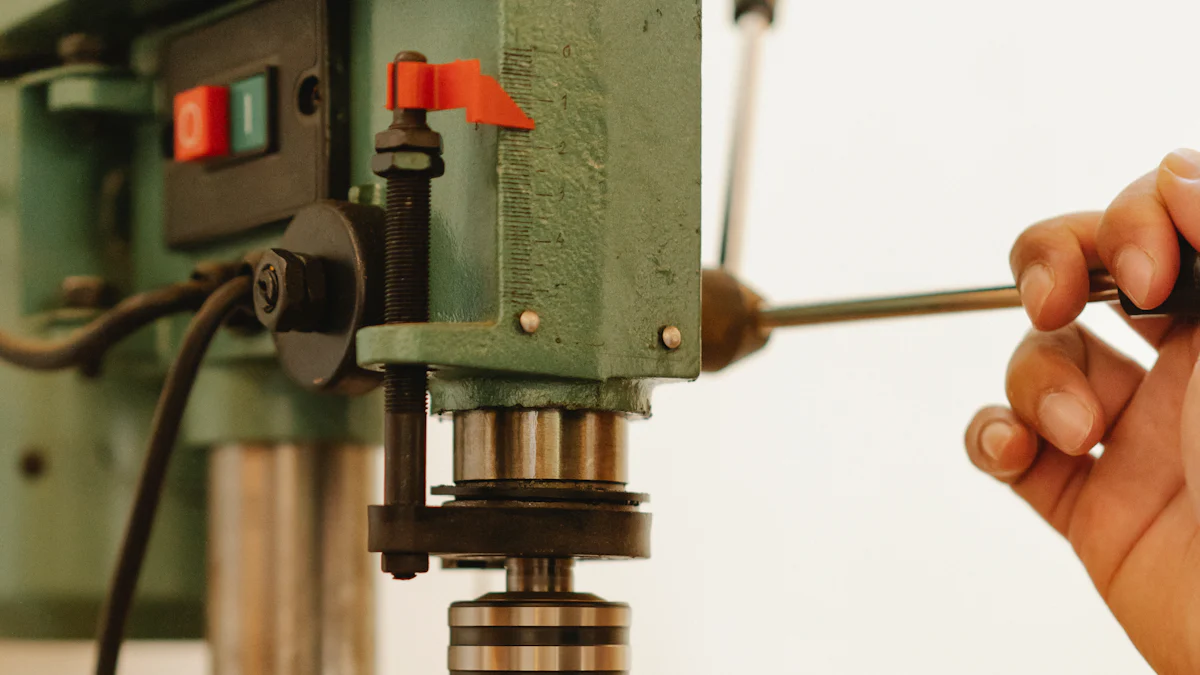

Precision remains the key to mastering the heavy-duty circle cutter for a drill press. Proper setup and meticulous measurements ensure clean and accurate cuts.

Setting Up the Drill Press

Choosing the Right Speed

Selecting the appropriate speed for the drill press is crucial. The heavy-duty circle cutter operates best at speeds below 500 RPM. Higher speeds can cause overheating and reduce the lifespan of the tool. Always refer to the manufacturer’s guidelines for optimal performance.

Adjusting the Table Height

Adjusting the table height ensures the workpiece aligns correctly with the circle cut tool. Lower the table to accommodate thicker materials. Raise it for thinner sheets. Proper alignment prevents uneven cuts and enhances precision.

Aligning the Circle Cutter

Aligning the circle cutter involves positioning the tool accurately on the drill press. Secure the cutter in the chuck, ensuring it is centered. Misalignment can lead to off-center cuts and potential damage to the workpiece.

Marking and Measuring

Using a Center Punch

A center punch creates an indentation at the center of the intended circle. This indentation guides the drill bit, preventing it from wandering. Accurate placement of the center punch marks the beginning of a precise cut.

Measuring the Diameter

Measuring the diameter of the circle ensures the cut matches the project requirements. Use a ruler or caliper to measure the desired diameter. Adjust the circle cutter accordingly. Accurate measurements guarantee the final product meets specifications.

Ensuring Symmetry

Symmetry in circle cutting is vital for balanced and professional results. Double-check measurements and alignments before starting the drill. Symmetrical cuts enhance the aesthetic and functional quality of the project.

Cutting Process

Starting the Drill

Start the drill press at a low speed to initiate the cut. Gradually increase the speed if necessary, but never exceed the recommended RPM. A controlled start reduces the risk of errors and improves the quality of the cut.

Applying Steady Pressure

Applying steady pressure ensures a smooth and even cut. Avoid forcing the cutter through the material. Let the drill press and the circle cut tool do the work. Consistent pressure maintains the integrity of the tool and the workpiece.

Monitoring Progress

Monitoring progress during the cutting process helps detect any issues early. Regularly check the alignment and depth of the cut. Adjustments may be necessary to maintain precision. Continuous monitoring ensures a successful outcome.

Alternatives to Heavy-Duty Circle Cutters

Hole Saws

Advantages

Hole saws offer several benefits for cutting circles. These tools provide a straightforward and efficient method for creating holes in various materials. The design of hole saws allows for quick setup and easy operation. Users can achieve clean cuts with minimal effort. Hole saws are available in multiple sizes, catering to different project needs.

Disadvantages

Despite their advantages, hole saws have limitations. These tools often struggle with thicker or harder materials. The cutting process can generate significant heat, leading to potential tool damage. Hole saws may also produce rougher edges compared to a dedicated circle cut tool. Users must frequently replace the blades due to wear and tear.

Jigsaws with Circle Cutting Attachments

Advantages

Jigsaws equipped with circle cutting attachments provide versatility. These tools can handle a wide range of materials, from wood to metal. The adjustable nature of the attachments allows for precise diameter settings. Users can achieve intricate cuts with a jigsaw, making it suitable for detailed projects. The portability of jigsaws adds to their convenience.

Disadvantages

However, jigsaws with circle cutting attachments come with challenges. Maintaining consistent pressure and speed can be difficult, affecting the cut quality. The attachments may require frequent adjustments to ensure accuracy. Jigsaws generally produce more vibration, which can lead to uneven cuts. These tools also tend to be noisier, necessitating hearing protection.

CNC Machines

Advantages

CNC machines represent the pinnacle of precision and automation in circle cutting. These machines offer unparalleled accuracy, capable of producing intricate designs with ease. Users can program CNC machines to cut circles of any size, ensuring consistency across multiple pieces. The automation reduces manual labor, increasing efficiency and productivity.

Disadvantages

The high cost of CNC machines presents a significant barrier for many users. These machines require substantial investment, both in terms of initial purchase and ongoing maintenance. Operating CNC machines demands specialized knowledge and training. The setup process can be time-consuming, particularly for complex projects. Despite their capabilities, CNC machines may not be practical for smaller workshops or hobbyists.

Mastering the heavy-duty circle cutter for a drill press involves understanding safety and precision. Adhering to safety guidelines ensures a secure working environment. Precision techniques enhance the quality of the cuts. The circle cut tool proves invaluable for various materials and projects. Future content will explore advanced drilling techniques and tool maintenance, providing further insights for achieving professional results.

See Also

Scooter Upgrades: High-Quality Parts for Maximum Performance

Winter Comfort: Stay Cozy with Plush Socks and Towels

Dive into Diverse Sock Options for Both Genders