Using the right rock cutting tools ensures precision and efficiency in stonework. Various tools cater to different types of rocks and cutting needs. Safety and preparation play crucial roles in successful rock cutting. Proper setup and protective gear prevent accidents and enhance performance.

Understanding Different Rock Cutting Tools

Hand Tools

Chisels

Chisels serve as fundamental rock cutting tools for many stonework projects. These tools come in various shapes and sizes, each designed for specific tasks. A flat chisel works well for creating smooth surfaces, while a pointed chisel excels at detailed carving. The use of chisels requires precision and control to avoid damaging the rock.

Hammers

Hammers complement chisels in rock cutting. A stonemason’s hammer, also known as a brick hammer, features a dual-sided head. One side has a flat face for striking chisels, and the other side has a pointed end for breaking rocks. Proper use of hammers involves controlled strikes to ensure accurate cuts and minimize rock fractures.

Power Tools

Angle Grinders

Angle grinders are versatile rock cutting tools equipped with rotating abrasive discs. These tools can cut, grind, and polish rocks efficiently. Diamond blades, often used with angle grinders, enhance cutting precision and durability. Users must handle angle grinders with care to maintain control and achieve clean cuts.

Rotary Tools

Rotary tools offer precision in detailed rock cutting tasks. These tools use various attachments, such as diamond-tipped bits, to carve intricate designs and shapes. Rotary tools operate at high speeds, making them ideal for fine work. Users must maintain a steady hand to achieve desired results.

Specialized Tools

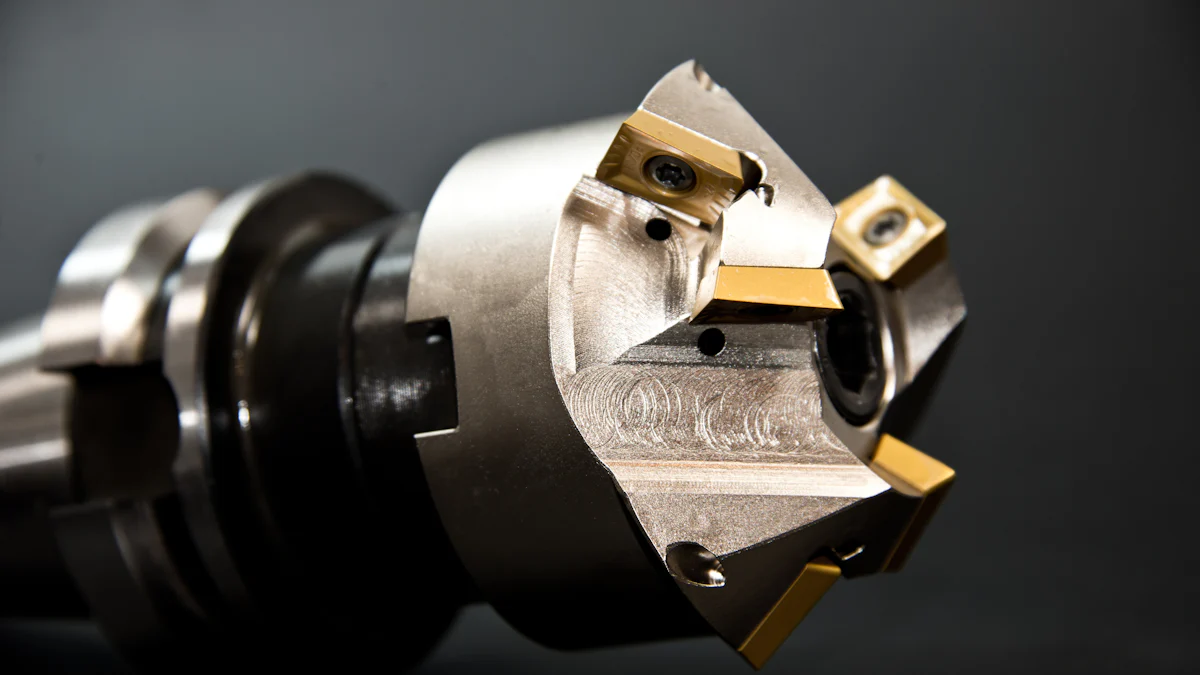

Diamond Blades

Diamond blades stand out among specialized rock cutting tools. These blades feature industrial-grade diamonds embedded in the cutting edge, providing exceptional hardness and durability. Diamond blades excel in cutting through hard materials like granite and marble. Their use ensures smooth and precise cuts with minimal effort.

Wire Saws

Wire saws represent advanced rock cutting tools for large-scale projects. These tools use a continuous loop of wire coated with diamond abrasives to cut through massive rock formations. Wire saws offer precision and efficiency, making them suitable for quarrying and mining operations. Proper setup and tensioning of the wire ensure optimal performance.

Techniques for Effective Rock Cutting

Preparation

Selecting the right tool

Choosing the appropriate rock cutting tools is crucial for achieving precise and efficient results. Different rocks require specific tools due to their varying hardness and composition. For instance, granite demands diamond blades, while softer stones like limestone can be cut with standard masonry blades. Understanding the characteristics of the rock helps in selecting the most effective tool. This ensures a smoother cutting process and reduces the risk of damaging the material.

Setting up the workspace

A well-organized workspace enhances safety and efficiency when using rock cutting tools. Begin by securing the rock firmly in a vise or clamp to prevent movement during cutting. Ensure that the work area is well-lit and free from obstructions. Proper ventilation is essential, especially when using power tools that generate dust and debris. Additionally, having all necessary tools and protective equipment within reach minimizes interruptions and maintains focus on the task.

Cutting Techniques

Hand Tool Techniques

Hand tools like chisels and hammers require skill and precision. Start by marking the cutting line on the rock with a pencil or chalk. Position the chisel along the line and strike it with a hammer using controlled, even blows. Gradually deepen the groove until the rock splits. Patience and steady hands are vital to avoid unwanted fractures. Regularly inspect the chisel for wear and sharpen it as needed to maintain effectiveness.

Power Tool Techniques

Power tools offer speed and precision in rock cutting. Angle grinders equipped with diamond blades can handle tough materials like granite and marble. When using an angle grinder, apply gentle pressure and let the blade do the work. Avoid forcing the tool, which can lead to uneven cuts and potential accidents. Rotary tools with diamond-tipped bits excel in detailed work. Maintain a steady hand and follow the marked lines carefully. Regularly check the tool’s attachments for wear and replace them to ensure optimal performance.

Safety Measures and Best Practices

Personal Protective Equipment (PPE)

Essential PPE for rock cutting

Using rock cutting tools requires appropriate Personal Protective Equipment (PPE). Essential PPE includes:

- Safety goggles: Protect eyes from flying debris and dust.

- Hearing protection: Safeguard ears from the loud noise produced by power tools.

- Dust masks or respirators: Prevent inhalation of harmful dust particles.

- Gloves: Shield hands from sharp edges and vibrations.

- Steel-toed boots: Protect feet from falling rocks and heavy tools.

Wearing the correct PPE minimizes the risk of injuries and ensures a safer working environment.

Proper usage and maintenance

Proper usage and maintenance of PPE are crucial. Always inspect PPE before use. Check for any signs of wear or damage. Replace damaged equipment immediately. Follow the manufacturer’s instructions for proper usage. Clean PPE regularly to maintain its effectiveness. Store PPE in a dry, clean place to prevent contamination and damage.

Tool Maintenance

Regular inspection

Regular inspection of rock cutting tools ensures optimal performance and safety. Examine tools for any signs of wear or damage. Check blades for sharpness and integrity. Inspect power tools for electrical issues and mechanical defects. Address any issues promptly to prevent accidents and ensure efficient operation.

Cleaning and storage

Proper cleaning and storage of rock cutting tools extend their lifespan. Clean tools after each use to remove dust and debris. Use appropriate cleaning agents and methods as recommended by the manufacturer. Dry tools thoroughly to prevent rust and corrosion. Store tools in a cool, dry place. Organize tools properly to avoid damage and ensure easy access for future use.

Effective rock cutting requires the right tools and techniques. Safety measures, such as using personal protective equipment, are essential. Regular tool maintenance ensures optimal performance. Practicing these methods leads to successful stonework projects.

“I saw a neat suggestion on here not too long ago, where someone had retro-fitted a gas powered edger with a diamond blade, and used that for cutting rocks in the field.” — Unknown

Readers are encouraged to share their experiences and tips. Engaging with the community fosters learning and improvement.

See Also

Discovering the Assortment of Socks for Males and Females

Top Tips for Warm Winter with Soft Comfort Towel Socks