Maintaining a torque wrench set is paramount for optimal performance and longevity. By caring for your torque wrench set, you ensure accurate torque measurements and prevent premature replacements. In this guide, we will delve into the essential steps to keep your tools in top condition. From cleaning procedures to calibration processes, each aspect plays a crucial role in the lifespan of your equipment.

Importance of Maintenance

When it comes to torque wrench set care, prioritizing maintenance is key to ensuring the longevity and accuracy of your tools. Studies have consistently shown that regular maintenance, inspection, and calibration play a vital role in maintaining the precision of torque measurements. It is crucial to invest time in caring for your equipment to prevent unexpected downtime and costly replacements.

Extending Lifespan

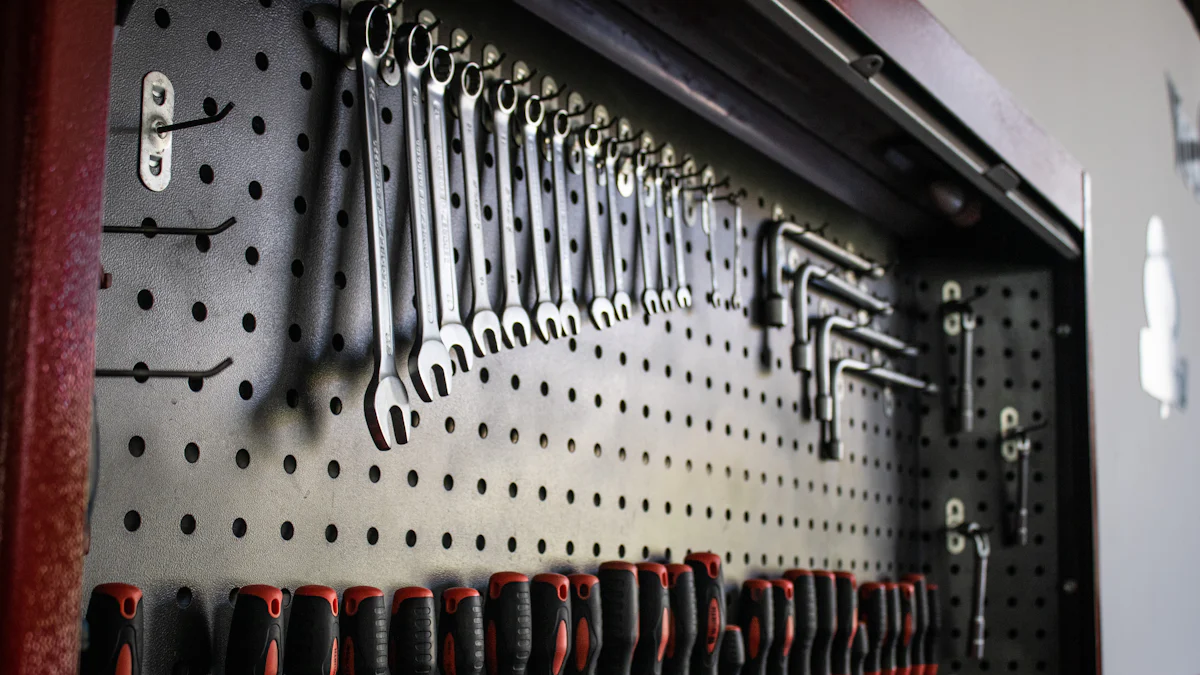

Proper care starts with regular cleaning of your torque wrench set. By removing dirt and debris accumulated during use, you not only maintain the tool’s performance but also prevent potential inaccuracies in torque readings. Additionally, proper storage is essential to protect your equipment from environmental factors that could lead to rust or damage over time.

Ensuring Accuracy

Maintaining accuracy requires more than just occasional checks. Regular calibration is necessary to verify that your torque wrench set provides precise measurements consistently. By calibrating at recommended intervals, you can ensure that your tools are always reliable. Furthermore, checking for wear on components such as handles or indicators is crucial in identifying any potential issues early on.

Safety Considerations

Safety should always be a top priority when working with tools like torque wrench sets. By preventing accidents through proper maintenance practices, you create a safer working environment for yourself and others. Always follow manufacturer guidelines regarding usage and maintenance to guarantee optimal performance and safety standards are met.

Cleaning and Storage

Cleaning Procedures

Tools Needed

- Soft-bristled brush

- Mild detergent

- Clean cloth

- Lubricating oil

Step-by-Step Guide

- Begin by inspecting your torque wrench for any visible dirt or debris.

- Use a soft-bristled brush to gently remove any particles from the surface of the wrench.

- Prepare a mixture of mild detergent and water in a container.

- Dip the clean cloth into the soapy solution and wring out excess liquid.

- Wipe down the torque wrench, focusing on areas with stubborn grime or residue.

- Rinse the cloth thoroughly and wipe the wrench again to remove any soap residue.

- Dry the torque wrench completely using a dry cloth to prevent moisture buildup.

- Apply a small amount of lubricating oil to moving parts for smooth operation.

Storage Tips

Environment Conditions

- Store your torque wrench in a dry place to prevent moisture-related damage.

- Avoid exposing the wrench to extreme temperatures or direct sunlight.

- Keep the tool away from corrosive substances that could degrade its materials.

Storage Solutions

- When not in use, return your torque wrench to its designated case for protection.

- If storing multiple wrenches together, consider using a hook or drawer organizer to prevent tangling.

- Regularly clean your torque wrench after each use to prevent corrosion and maintain performance over time.

By following these cleaning and storage practices, you can ensure that your torque wrench remains in optimal condition for accurate measurements and longevity. Remember, proper care today will extend the lifespan of your tools and save you from costly replacements in the future.

Calibration and Inspection

Calibration Process

Calibration of torque wrenches is a critical step in ensuring accurate measurements. By attaching the wrench to a calibration tool and applying predetermined torque forces, you can verify its precision. This process compares readings to industry standards, guaranteeing reliable performance.

Frequency of Calibration

Regular calibration is essential for maintaining accuracy. It is recommended to calibrate your torque wrench at least once per year to ensure consistent and precise readings. By adhering to this schedule, you can prevent costly errors due to inaccurate measurements.

How to Calibrate

To calibrate your torque wrench effectively, follow these steps:

- Attach the wrench securely to the calibration tool.

- Apply the specified torque force as indicated.

- Compare the readings on the wrench with the expected values.

- Make any necessary adjustments to align the measurements accurately.

Inspection Tips

Inspecting your torque wrench regularly is crucial for identifying wear and damage early on. By conducting thorough inspections, you can address potential issues promptly, ensuring safety and accuracy in your work environment.

Identifying Wear and Damage

Look for signs of wear on components such as handles or indicators. Any visible damage should be addressed immediately to prevent further issues that could affect performance.

Addressing Issues Early

By addressing any identified issues early on, you can prevent accidents and maintain the reliability of your torque wrench set. Regular inspections help in detecting problems before they escalate, ultimately saving you time and resources in the long run.

Regular maintenance of torque wrench sets is not just a task; it’s a commitment to prolonging their lifespan and ensuring accurate measurements. By following the key steps of cleaning, calibration, and inspection, users can guarantee the reliability of their tools. Testimonials from various users highlight the significant impact of consistent care on the long-term use of torque wrenches. Remember, investing time in maintenance today will save you from costly replacements tomorrow. Keep your tools in top condition to continue achieving successful projects with precision and safety.