In the realm of manufacturing, the thread cutting tool stands as a vital instrument, enabling precise and accurate thread creation across various industries. Recent advancements in this field have led to the development of innovative tools with enhanced durability and efficiency. The demand for customized solutions further propels market growth, catering to the evolving needs of sectors like automotive, aerospace, and manufacturing. This blog aims to delve into these advancements, highlighting their significance and impact on industry evolution.

In the realm of manufacturing, the thread cutting tool stands as a vital instrument, enabling precise and accurate thread creation across various industries. Recent advancements in this field have led to the development of innovative tools with enhanced durability and efficiency. The demand for customized solutions further propels market growth, catering to the evolving needs of sectors like automotive, aerospace, and manufacturing. This blog aims to delve into these advancements, highlighting their significance and impact on industry evolution.

The Evolution of Thread Cutting Tools

Manual Thread Cutting

In the early stages of industrial development, craftsmen relied on manual techniques to create threads on workpieces. Thread cutting tools were meticulously operated by skilled workers, ensuring the precision and uniformity of each thread. These tools, such as taps and dies, played a fundamental role in shaping the mechanical landscape of that era. The process involved carefully guiding the cutting tool onto the material to carve out the desired thread profile.

Introduction of Machine Tools

With technological advancements came the introduction of machine tools for thread cutting. These innovative devices revolutionized manufacturing processes by automating and streamlining thread creation. Thread cutting tools, now powered by machinery, could produce threads at a faster pace with increased accuracy. This shift from manual labor to mechanized operations marked a significant leap forward in industrial efficiency and productivity.

Modern Advancements

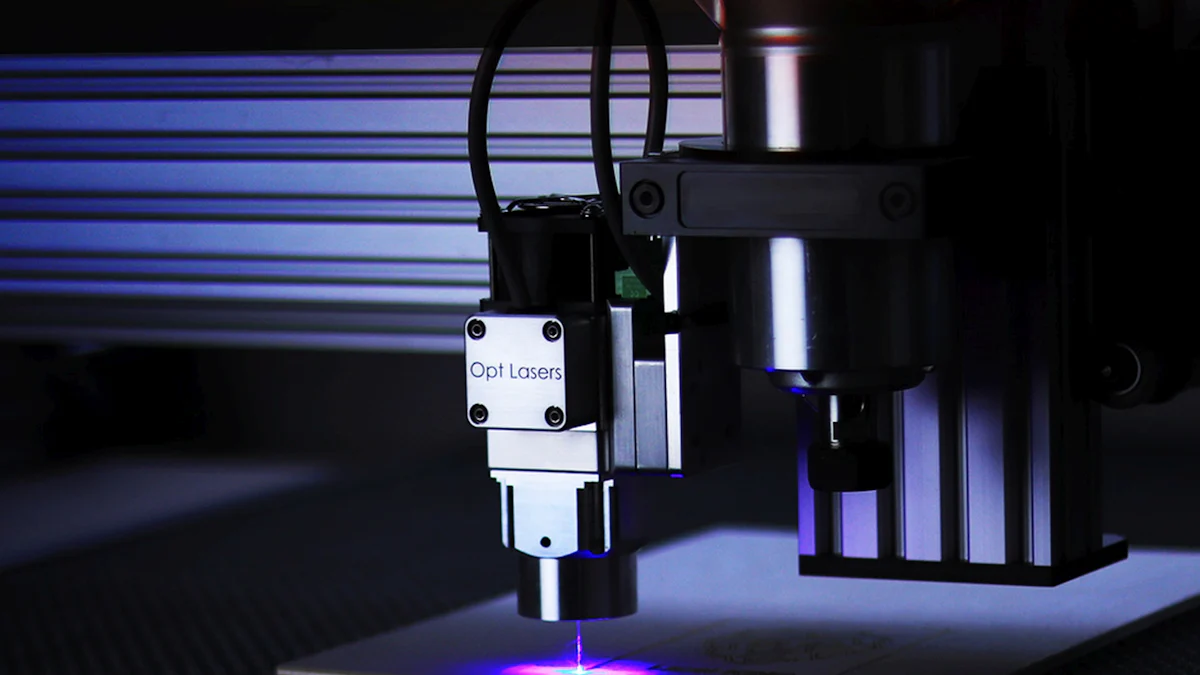

CNC Machines

The advent of Computer Numerical Control (CNC) machines further transformed the realm of thread cutting. These automated systems allowed for intricate and complex thread designs to be executed with unparalleled precision. CNC technology enabled manufacturers to achieve high levels of customization and repeatability in their threaded components, catering to diverse industry requirements.

Single-Point Screw-Cutting

Another notable advancement in modern thread cutting tools is the technique known as single-point screw-cutting. This method involves guiding a single-point cutting tool along a rotating workpiece to create precise screw threads. By utilizing this approach, manufacturers can achieve exceptional thread quality while minimizing material waste and production time.

Innovations in Thread Cutting Tools

New Product Lines

Emuge Thread Mills

Emuge Thread Mills are specialized tools designed for creating internal or external threads in CNC machining operations. These mills offer high precision and are particularly suitable for complex thread geometries. Their innovative design ensures optimal performance, making them a top choice for manufacturers seeking superior thread cutting solutions.

Seco Tools Taps

Seco Tools Taps encompass a wide range of threading tools essential for creating threads on various objects like screws, bolts, and nuts. These taps play a crucial role in industries requiring precise threading, such as automotive, aerospace, construction, and manufacturing. With advanced features and exceptional durability, Seco Tools Taps provide reliable solutions for diverse threading applications.

Advanced Techniques

Thread Whirling

Thread whirling introduces a unique approach to thread cutting by utilizing inserts mounted on the inside of a cutting ring. This innovative technique differs from traditional methods like thread milling and enables the creation of intricate thread profiles with enhanced efficiency. Manufacturers benefit from improved productivity and superior thread quality when implementing thread whirling in their operations.

Surface Texturing

Surface texturing plays a vital role in enhancing the cutting performance of tools used for thread creation. By incorporating techniques like CNT-enriched nanofluid lubrication, manufacturers can achieve smoother surface finishes and reduce friction during the cutting process. This results in extended tool life and improved overall efficiency in threading operations.

Benefits of Modern Thread Cutting Tools

Increased Efficiency

Faster Production Times

Modern thread cutting tools offer a significant advantage in terms of efficiency, particularly in accelerating production timelines. By utilizing these advanced tools, manufacturers can expedite the thread creation process, leading to quicker turnaround times for their projects. The enhanced speed at which threads can be accurately cut translates to improved overall productivity within manufacturing operations.

Reduced Tool Wear

One notable benefit of adopting modern thread cutting tools is the minimized wear experienced by the cutting implements. These innovative tools are engineered with durable materials and cutting-edge designs that enhance their longevity and resilience. As a result, manufacturers can rely on these tools for prolonged periods without facing the frequent need for replacements or maintenance, reducing downtime and operational costs.

Enhanced Precision

Consistent Thread Quality

The precision offered by modern thread cutting tools ensures a consistent quality in every thread produced. Manufacturers can achieve uniformity in thread dimensions and profiles, meeting stringent industry standards with ease. This consistency not only enhances the aesthetic appeal of threaded components but also contributes to the overall functionality and reliability of the end products.

Compatibility with Difficult Materials

Another compelling advantage of modern thread cutting tools is their compatibility with a wide range of challenging materials. Whether working with exotic alloys, hardened steels, or composite materials, these tools exhibit exceptional performance and adaptability. Manufacturers can confidently tackle threading tasks on difficult substrates, expanding their capabilities and catering to diverse project requirements.

- To summarize, the evolution of thread cutting tools has significantly impacted manufacturing processes, enhancing efficiency and precision.

- Embracing innovative tools like Emuge Thread Mills and Seco Tools Taps offers manufacturers a competitive edge in diverse applications.

- The future of thread cutting technology promises continued advancements, catering to evolving industry demands and pushing boundaries in threaded component production.