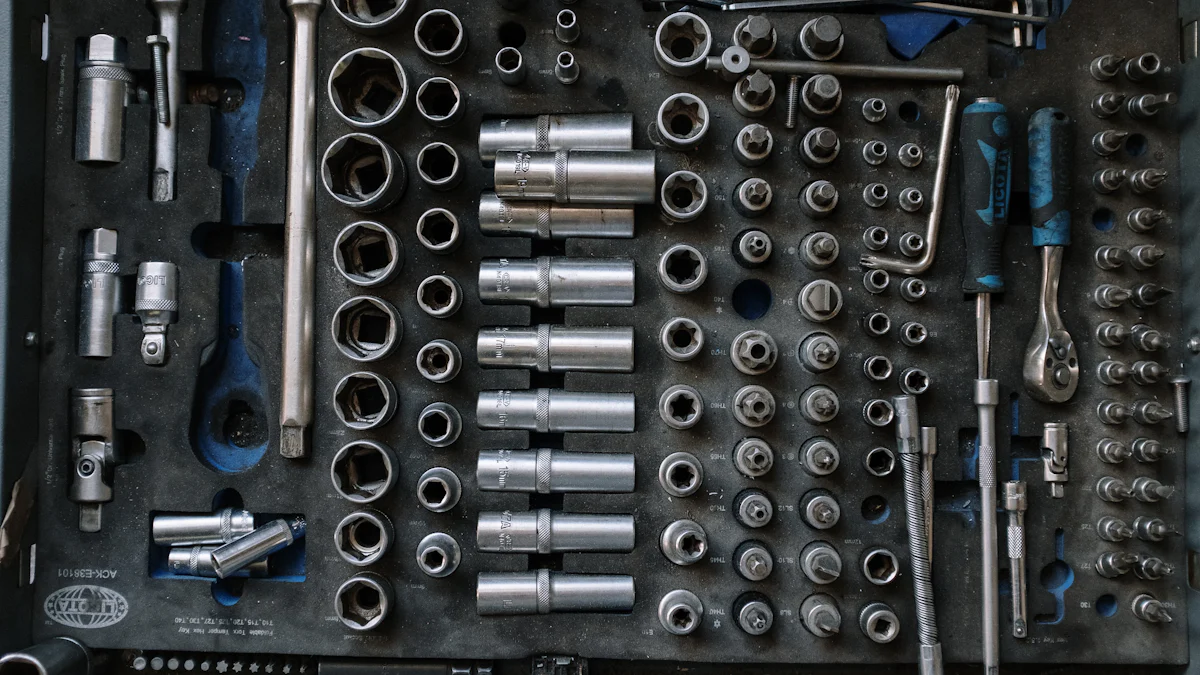

Industrial maintenance plays a pivotal role in ensuring operational efficiency and cost-effectiveness within various industries. The utilization of specialized tools, such as spanner nut sockets, is essential for maintaining equipment reliability and minimizing downtime. This blog will delve into the significance of industrial maintenance practices, emphasizing the critical role that Spanner nut sockets play in facilitating smooth maintenance operations across different sectors.

The Importance of Spanner Nut Sockets

When considering Spanner nut sockets, it is crucial to acknowledge their exceptional features and benefits that contribute significantly to industrial maintenance tasks. These specialized tools are crafted with precision, utilizing high carbon steel construction that ensures robustness and longevity in various operational conditions. The incorporation of heat treatment further enhances their durability, making them reliable assets for maintenance professionals across industries.

The feature of high carbon steel construction sets spanner nut sockets apart by providing a sturdy foundation for tackling challenging nuts with ease. This premium-quality material guarantees resilience against wear and tear, offering a long-lasting solution for demanding maintenance applications. Additionally, the heat treatment process reinforces the structural integrity of these sockets, elevating their performance and reliability during intensive use.

Utilizing spanner nut sockets presents numerous advantages that streamline maintenance operations effectively. One notable benefit is the secure fastening capability they offer, ensuring precise tightening and loosening of spanner nuts without compromising on safety or efficiency. Moreover, their design promotes efficiency in maintenance tasks, enabling swift and accurate handling of various fastening components within industrial machinery.

Applications in Industrial Maintenance

In the Automotive Industry, professionals rely on spanner nut sockets for various essential tasks. When it comes to adjusting clutch nuts, these specialized tools provide a secure grip and precise control, ensuring optimal performance of the clutch system. Additionally, in the process of removing wheel bearing locknuts, spanner nut sockets offer a reliable solution for efficiently disassembling and maintaining wheel bearings without causing damage.

Within the Manufacturing Sector, the versatility of spanner nut sockets shines through in handling different types of fasteners. Specifically, when dealing with bearing lock nuts, these sockets enable seamless tightening and loosening procedures, contributing to the smooth operation of machinery. Moreover, for other industrial fasteners, such as bolts and screws, spanner nut sockets prove invaluable in ensuring proper maintenance and upkeep of equipment.

Professionals across industries recognize the indispensable nature of spanner nut sockets in addressing diverse maintenance challenges. Whether it’s adjusting components in automotive systems or securing fasteners in manufacturing equipment, these specialized tools play a crucial role in enhancing operational efficiency and reliability.

Choosing the Right Spanner Nut Socket

When selecting a spanner nut socket, professionals must consider crucial factors to ensure optimal performance and compatibility with various industrial applications. The range of sizes available in these specialized tools caters to a diverse array of spanner nuts, offering versatility and precision in maintenance tasks. Ensuring a proper fit is essential to guarantee seamless operation and avoid any potential risks associated with incorrect tool usage.

Professionals can explore different brands that specialize in manufacturing high-quality spanner nut sockets. Motion Pro stands out as a reputable provider known for its innovative designs and reliable performance across different industries. Their commitment to quality and durability makes them a preferred choice among maintenance experts seeking top-notch tools for their operations.

Another noteworthy brand in the realm of spanner nut sockets is Ingersoll Rand, renowned for its precision-engineered tools tailored for specific applications like air compressors. Professionals can trust Ingersoll Rand’s products to deliver consistent results and exceptional durability, ensuring long-term usability in demanding industrial environments.

Considering the importance of selecting the right spanner nut socket, professionals should prioritize size compatibility and brand reputation when making their choices. By investing in high-quality tools from trusted brands like Motion Pro or Ingersoll Rand, maintenance professionals can enhance their efficiency and effectiveness in handling spanner nuts across various industrial settings.

Reiterating the indispensable role of spanner nut sockets in industrial maintenance, these specialized tools are vital for ensuring efficient and reliable equipment upkeep. By emphasizing their robust features and benefits, professionals can enhance maintenance operations across diverse sectors. Moving forward, professionals should prioritize investing in high-quality spanner nut sockets from reputable brands like Motion Pro or Ingersoll Rand to optimize performance and durability. Embracing these advanced tools will undoubtedly elevate maintenance practices, promoting seamless operations and long-term equipment reliability in industrial settings.